The textile industry is one of the largest contributors to environmental pollution.

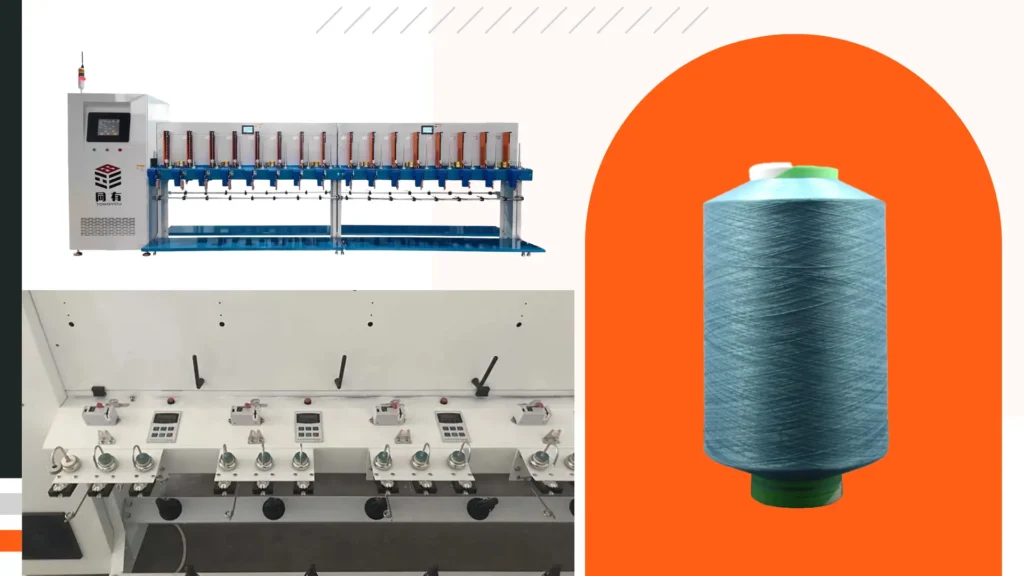

However, advancements in automation technology have made it possible to produce textiles in a more sustainable manner.

This article explores how automation equipment is transforming the textile industry into a greener, more efficient sector.

How Does Automation Equipment Reduce Waste?

Minimizing Material Waste

Automation technologies significantly enhance precision in cutting and sewing processes.

By utilizing computer-controlled machines, manufacturers can ensure that fabric is utilized to its fullest potential, resulting in minimal waste.

Traditional methods often lead to irregular cuts and excess fabric, but automated systems can optimize patterns and layouts, dramatically reducing leftover material.

This not only conserves resources but also cuts costs, making production more economical.

Efficient Resource Management

Automated systems can monitor and adjust resource usage in real-time.

For example, sensors can track the amount of fabric being used and adjust the machinery accordingly to avoid overuse.

This type of intelligent resource management ensures that every material is used effectively, minimizing waste while maintaining production efficiency.

By optimizing the input of materials, companies can lower their overall environmental impact.

Recycling and Reusing Materials

Automation facilitates the sorting and processing of textile waste, allowing for recycling and repurposing of materials that would otherwise end up in landfills.

Automated sorting machines can quickly identify and separate different types of fabric, making it easier to recycle them.

This process not only reduces landfill waste but also supports a circular economy, where materials are continually reused, thereby minimizing the need for new resources.

What Role Does Automation Play in Energy Efficiency?

Smart Energy Management Systems

Automation can optimize energy use by controlling machinery and processes based on real-time data, leading to reduced energy consumption.

For instance, smart systems can turn off machines during idle times or adjust power levels according to the specific needs of the production process.

This proactive approach to energy management can lead to significant cost savings and a reduced carbon footprint.

Integration of Renewable Energy Sources

Automated systems can seamlessly integrate renewable energy sources, such as solar or wind energy, into production lines.

This integration not only reduces reliance on fossil fuels but also helps companies meet their sustainability goals.

By using clean energy, manufacturers can significantly lower their environmental impact while also benefiting from potential cost savings associated with renewable energy sources.

Reducing Downtime and Enhancing Productivity

With automation, machinery operates more efficiently, reducing downtime and energy waste associated with manual interventions and repairs.

Automated systems can perform routine maintenance checks and alerts, ensuring that equipment operates at peak efficiency.

By minimizing downtime, companies can maintain high levels of productivity while also reducing energy consumption during idle periods.

How Can Automation Enhance Water Conservation?

Precision in Water Usage

Automated dyeing and finishing processes can use water more efficiently, minimizing waste and pollution.

Advanced technologies allow for precise control over the amount of water used in these processes, ensuring that only the necessary amount is consumed.

This precision is crucial in an industry where water is often wasted, contributing to significant environmental concerns.

Closed-Loop Water Systems

Automation allows for the implementation of closed-loop systems that recycle water within the production process.

This means that water used in dyeing and finishing can be filtered and reused, drastically reducing overall water consumption.

Such systems not only conserve water but also help in managing wastewater, ensuring that harmful chemicals are treated before being released into the environment.

Monitoring and Control

Automated systems can continuously monitor water quality and usage, ensuring that any leaks or inefficiencies are promptly addressed.

Sensors can detect changes in water quality, allowing for immediate adjustments to the production process.

This level of monitoring helps maintain high standards of quality while also conserving resources, making the production process more sustainable.

In What Ways Does Automation Improve Labor Conditions?

Reducing Physical Strain on Workers

Automation takes over repetitive and physically demanding tasks, reducing the risk of injury and improving overall workplace safety.

By alleviating the physical burden placed on workers, companies can create a healthier and more productive work environment.

This shift not only benefits employees but also enhances overall operational efficiency.

Upskilling Opportunities

As automation technologies advance, workers are offered training to operate sophisticated machinery, enhancing their skill sets and career prospects.

Companies that invest in employee training not only prepare their workforce for the future but also foster a culture of continuous improvement.

This investment in human capital can lead to higher job satisfaction and loyalty among employees.

Enhanced Job Satisfaction

With less monotonous work, employees can focus on more creative and strategic tasks, leading to higher job satisfaction and retention rates.

Automating routine tasks allows workers to engage in more meaningful work, which can enhance their overall job satisfaction and motivate them to contribute positively to the organization.

How Does Automation Support Sustainable Supply Chains?

Transparency and Traceability

Automated systems provide real-time data on material sourcing and production processes, enhancing transparency and sustainability in supply chains.

By tracking materials from their origin to the final product, companies can ensure that they are sourcing responsibly and ethically.

This transparency builds trust with consumers who are increasingly concerned about the ethical implications of their purchases.

Streamlined Logistics

Automation optimizes inventory management and logistics, reducing the carbon footprint associated with transportation and storage.

Automated inventory systems can predict demand more accurately, minimizing excess stock and the associated costs of storage and waste.

This efficiency not only benefits the environment but also improves the bottom line for companies.

Collaboration with Eco-Friendly Suppliers

Automation facilitates partnerships with suppliers who prioritize sustainability, ensuring that raw materials are sourced responsibly.

Companies can use automated systems to evaluate supplier practices, ensuring alignment with their sustainability goals.

This collaboration can lead to a more responsible supply chain, benefiting both the environment and the economy.

What Are the Economic Benefits of Automation in Green Textile Production?

Cost Savings

While the initial investment in automation may be significant, the long-term savings in labor, material, and energy costs can be substantial.

By optimizing production processes and reducing waste, companies can achieve significant cost reductions over time.

This financial benefit makes automation an attractive option for manufacturers looking to improve their bottom line.

Competitive Advantage

Companies that adopt automated green practices can differentiate themselves in the market, appealing to environmentally conscious consumers.

In an era where consumers are increasingly prioritizing sustainability in their purchasing decisions, having automated processes that emphasize green practices can provide a competitive edge.

Job Creation in New Areas

As automation changes the landscape of production, new jobs emerge in technology management, maintenance, and sustainability consulting.

While some traditional roles may be diminished, the rise of automation creates opportunities for skilled workers in emerging fields.

This shift can lead to a more dynamic job market that supports sustainable practices.

How Does Automation Contribute to Product Quality?

Consistency in Production

Automated processes ensure a high level of consistency in product quality, reducing defects and waste.

By standardizing production methods, companies can maintain strict quality control, leading to a more reliable end product.

This consistency is essential for building brand loyalty and trust among consumers.

Enhanced Testing and Quality Control

Automation allows for real-time quality checks, leading to faster identification of issues and improved product standards.

Automated testing systems can quickly detect defects, enabling manufacturers to address problems before they reach the consumer.

This proactive approach to quality control enhances overall product reliability.

Customization and Flexibility

Automated systems can quickly adapt to changes in design or production needs, allowing for greater customization without sacrificing quality.

This flexibility enables companies to respond to market trends and consumer preferences more effectively, ensuring that they remain competitive in a rapidly changing industry.

What Challenges Does Automation Face in Green Textile Production?

Initial Investment Costs

The upfront costs of implementing automation can be a barrier for some companies, especially smaller manufacturers.

The financial commitment required for automated systems may deter businesses from making the switch, despite the long-term benefits.

Finding ways to offset these costs through grants or partnerships can help ease this transition.

Technological Adaptation

Existing workforce may require training to adapt to new automated systems, which can take time and resources.

Companies must invest in comprehensive training programs to ensure employees are equipped to handle new technologies.

This adaptation period can create temporary disruptions in production but is essential for long-term success.

Balancing Automation with Human Touch

While automation brings many benefits, there remains a need for human creativity and intuition in textile design and production.

A successful balance between automation and human involvement can lead to innovative solutions that enhance both productivity and creativity.

Companies must navigate this balance to fully realize the potential of automation while still valuing human input.

Conclusion

Automation equipment plays a crucial role in facilitating green textile production by reducing waste, conserving energy and water, and improving labor conditions.

While challenges exist, the long-term benefits of adopting automation in the textile industry are significant.

Embracing these technologies not only supports sustainable practices but also positions companies for future success in a competitive market.

By investing in automation, the textile industry can move towards a greener future, benefiting both the environment and the economy.