What is a Winding Machine?

A winding machine refers to a specific kind of device engineered to wind wire, yarn, or tape onto spools, reels, or bobbins.

It finds its significance in several manufacturing processes, availing effectiveness and uniformity in the production of coils that make up many industries.

The automation in the winding processes saves much time and resources of the manufacturers, decreasing dependence on human labor. Besides, these machines guarantee tight and even winding of materials, maintaining a quite decent quality and performance of the final product.

Winding machines find wide application to speed up production, minimize defects, and provide better conditions for performing specific work in industries that rely on precision, such as electronics and textiles.

In general, winding machines are essential tools that contribute much to making modern manufacturing processes effective and efficient.

Product Recommend:

Automation

Most modern winding machines have incorporated advanced automation technology.

This feature has drastically reduced the involvement of manual labor, consequently cutting down labor costs, besides reducing human error in the process.

Automation increases production speed and consistency for a seamless workflow that can easily meet higher production output demands.

Precision

Because good winding machines can ensure that the winding is tight and even.

It is of great importance in applications where quality has a direct effect on the performance of the coil, an example being in the making of electrical components.

The uniformly wound materials produced by these machines help the manufacturers to achieve high standards and meet the set regulations within the industries.

Types of Winding Machines

Winding machines vary in type for specific applications and industries.

The differences in variety are important to note as many businesses are looking to select a suitable machine that will serve their needs in production.

Coil Winding Machines

Primarily, it is expected that electrical industry coil winding machines manufacture coils for transformers and inductors, aside from other electrical components.

In this area, machines offer accuracy and consistency, which are fundamental features that guarantee the efficient operation of electrical devices.

By nature, these machines can multitask different wire gauges and various coil configurations to meet various application needs.

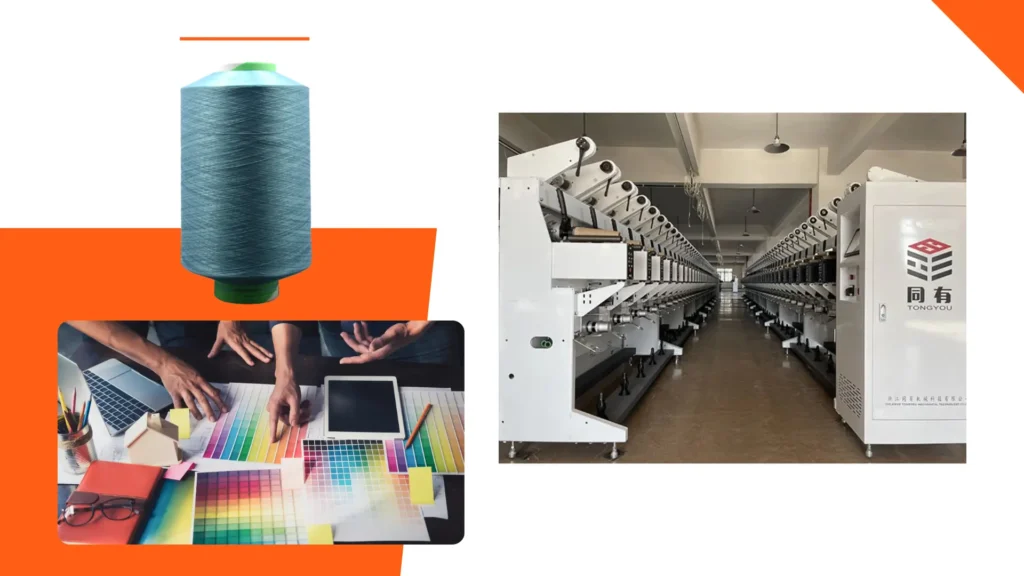

Textile Winding Machines

These machines are specially designed for the textile industry, with efficient winding of yarn and thread onto spools.

Such winding operations form a crucial part of creating different kinds of fabrics, sewing materials, and other textile products.

While doing so, it ensures neat and secure winding of yarn, thus enabling further processing and minimizing the chances of tangling or even damage while on storage.

Tape Winding Machines

These machines are used in the winding of adhesive tapes or electrical insulation tapes onto spools.

These are designed such that the tape is stored on these spools in an organized way, without tangling and damage, and is ready for packaging or electrical use.

For this reason, the precision of tape winding machines is highly important in sustaining tape integrity and functionality, especially where highly critical applications are involved.

Custom Winding Machines

Some businesses have special needs that can only be fulfilled by custom solutions. This may well be due to special characteristics of the material involved or the process applied during winding.

Such flexibility enables manufacturers to sharpen their production lines while responding to the needs of market niches, a sure way to gain competitive advantage.

Also Read:

- Top 10 Single Spindle Winding Machine Manufacturers in China

- Top 10 Textile Machinery Manufacturers in China

- Top 10 Yarn color card machine manufacturers in China

History and Evolution of Winding Machines

History and development of the winding machine stand as witness to some critical advancement of manufacturing technology and how the tool continuously adapted and responded to the ever-changing industrial demands.

Early Inventions

The first winders were very primitive hand-operated contraptions used in a multitude of small workshops.

These gave ground to more developed technologies that allow artisans to create wound products more efficiently than by hand.

Industrial Revolution

Revolution marked the turning point in manufacturing where mechanization introduced changes to most of the traditional ways of production.

Thus, this age created an era for winding machines that were capable of handling larger volumes of production and producing such items as textiles, electrical components, and other items-a situation that revolutionized their production.

These machines provided a base for mass production due to the increase in speed and efficiency.

Digital Age

Over the past few decades, several modern improvements have equipped the winding machines with computer controls, automation, and other forms of digital technology.

This recent wave in manufacturing allows flexibility in such ways as rapid adjustments to other materials and wind styles.

This is so because, as the industry keeps innovating, most of the modern-day winding machines are intelligent; they may independently monitor performance and optimize operations in real time.

Advantages of Using Winding Machines

The advantages of investing in winding machines are many, offering immense improvement in the production of items and efficiency in operation altogether.

High Efficiency

Automating the winding processes means companies are able to achieve faster production times.

Increased efficiency brings not only cost savings on labor but also increased production; it helps companies meet high demand without having to cut corners.

A well-managed workflow facilitated by winding machines may mean shorter lead times and increased customer satisfaction.

Consistency in Quality

Winding machines help provide uniform winding and, hence, highly qualitative products that can meet standard requirements.

This consistency helps in ensuring there is always customer satisfaction and reliability in those applications where quality is of essence.

It aids the manufacturer in reducing defects and returns, which in turn helps to create a good image in the market.

Diversity

The newer generation of winding machines has settings for materials and variable styles of winding.

This, in effect, means that these machines respond rapidly to continual market demands of change and customization of specific processes.

Products can be quickly changed without the involvement of much costly downtime, creating a great deal more flexibility.

Waste is Reduced

The precision of the winding machines ensures that as little material as possible is wasted, which in turn means that money is saved. Having optimization of materials used will not only help a company in sustainable development but also improve the bottom line.

Efficient production processes mean that fewer resources are wasted, which again goes in line with objectives of corporate social responsibility.

Common Industries Using Winding Machines

Winding machines are crucial in many industries that make the fabrication of simple products and their parts relevant to daily life.

Electrical Industry

Winding machines are used in producing coils employed in motors, generators, and transformers.

These are applied in nearly all electrical gadgets and appliances so much so that reliability and accuracy in winding machines ensure quality in electrical applications.

Textile Industry

The textile industry uses the winding machines in the making of fabrics, threads, and yarns.

The materials get wind neatly and tightly by the machines to avoid tangling of materials during storage and transportation.

The same reasons contribute to the quality of the product. Therefore, winding machines ensure efficiency in production.

Packaging Industry

In the packaging industry, winding machines are used to wind materials such as stretch films and adhesive tapes.

This is to ensure products are well packaged and ready to be distributed. Winding machines keep the integrity of packaging materials intact, which protects the product.

Automotive Industry

The winding machines play a great role in the production of wire harnesses and other electrical parts in vehicle manufacture.

The application indicated above-that precision and reliability are key at the production processes for vehicle manufacture-means quality is crucially important for the sake of safety and performance.

Conclusion

The winding machines are essential tools in modern manufacturing, as they provide a unique combination of efficiency, precision, and versatility across a wide range of industries.

From electrical components to textiles, their function contributes a great deal to the processes of production and to the quality of the products.

Considering how fast technology evolves, one would expect further developments regarding such winding machines, with automation and control systems that are even more sophisticated to adapt to changing market landscapes.

The proper winding machine investment will contribute significantly to enhancing the production capability and, more importantly, business profitability by ensuring quality and high efficiency.

The manufacturer must understand the different types of winding machines available, along with their applications, to allow them to make informed decisions leading to success in their operations.