Elasticity is a defining feature of high-quality knitted fabrics, ensuring they stretch comfortably, retain their shape, and stand up to repeated use.

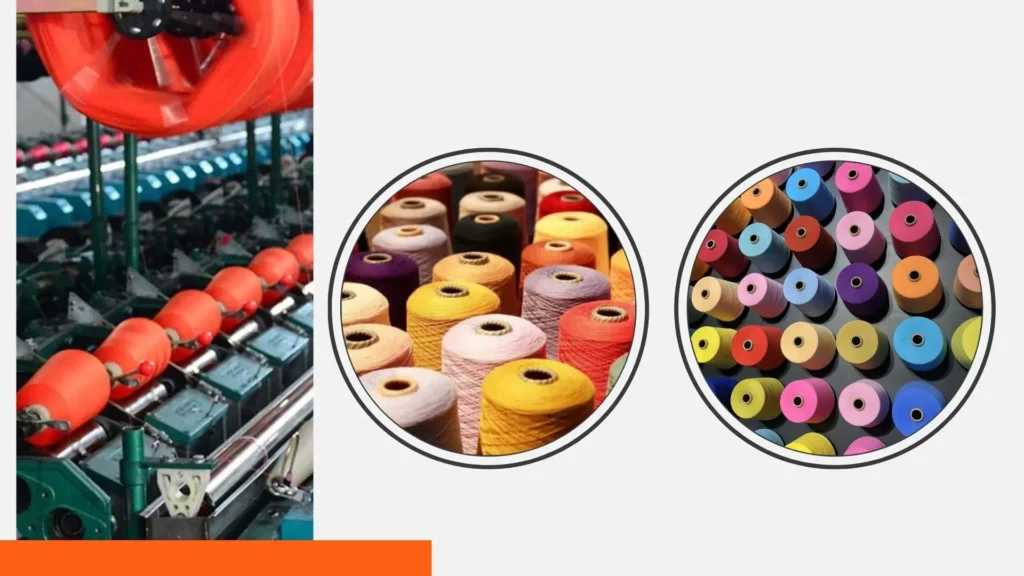

For manufacturers, achieving consistent, reliable elasticity in knitted textiles often comes down to the tools used in production—and the yarn doubling machine has emerged as a key player in this process.

Designed to twist two or more yarns together, this machine strengthens and refines yarns in ways that directly boost the elasticity of the final knitted fabric.

This article explains, in simple terms, how yarn doubling machines enhance elasticity in knitted fabrics, helping buyers understand their value in creating better, more durable textiles.

What Exactly Does a Yarn Doubling Machine Do?

It Twists Multiple Yarns Into One Stronger Strand

A yarn doubling machine takes two or more separate yarns and twists them together to form a single, unified strand.

This twisting process merges the yarns into a more robust structure, combining their individual strengths while adding new properties like elasticity.

The number of yarns used can vary—from two for lightweight fabrics to six or more for heavy-duty materials like industrial ropes.

It Improves Yarn Uniformity

Yarns can sometimes have slight variations in thickness or tension. By twisting them together, the doubling machine smooths out these inconsistencies, creating a more uniform yarn.

This uniformity ensures the final knitted fabric stretches evenly, without tight or loose spots.

Even minor irregularities in single yarns—like a thin section from uneven spinning—are masked when twisted with others, resulting in a more reliable base for manufacturing.

It Enhances Yarn Consistency During Knitting

Yarns that feed unevenly into knitting machines can cause defects in the fabric.

Doubled yarns, thanks to their twisted structure, flow more smoothly through knitting equipment, reducing snags and ensuring a consistent knit—critical for maintaining elasticity.

The twisted strand’s stability also minimizes breakages during knitting, which can disrupt production lines and create costly downtime.

And More:

- Price Comparison of Yarn Doubling Machine with Others

- Best Yarn Doubling Machine in China

- Troubleshooting Common Issues in Yarn Doubling Machines

How Does Twisting Yarns Boost Elasticity in Knitted Fabrics?

Twisting Creates Built-In “Give” in the Yarn

When yarns are twisted, they form a spring-like structure. This natural tension allows the yarn to stretch when pulled and bounce back to its original shape—exactly the elasticity needed in fabrics like activewear or socks.

The twist direction (clockwise or counterclockwise) can even be adjusted to fine-tune the “give,” with tighter twists offering firmer elasticity and looser twists providing softer stretch.

Combined Yarns Distribute Stress More Evenly

Single yarns can stretch too far or snap under pressure. Doubled yarns, with their twisted structure, distribute tension across multiple fibers.

This means when the fabric stretches, the stress is spread out, reducing the risk of overstretching and enhancing recovery.

Without this, repeated stretching could lead to permanent deformation.

The Twist Prevents Yarns From Separating When Stretched

In knitted fabrics, individual yarns can pull apart if stretched too much. Twisting them together locks the fibers in place, so even when the fabric is stretched, the yarns stay bonded, maintaining elasticity over time.

This bonding is particularly important for fabrics subjected to frequent stretching, such as baby clothes (which need to accommodate rapid growth) or athletic gear used daily.

Why is Elasticity in Knitted Fabrics So Important?

It Ensures Comfort in Wearable Textiles

Fabrics that stretch with the body—like those in shirts, leggings, or gloves—are far more comfortable.

Elasticity allows the fabric to move without restricting the wearer, a key feature in everyday and activewear.

This comfort factor directly influences consumer satisfaction, making elasticity a top priority for apparel brands.

It Helps Fabrics Retain Their Shape

Without elasticity, knitted fabrics can stretch out and lose their fit after a few wears—think of a sock that becomes baggy at the heel.

Elasticity ensures fabrics bounce back, keeping their original shape even after repeated use.

This shape retention extends the garment’s lifespan, reducing the need for frequent replacements.

It Enhances Durability in High-Use Areas

Areas like the knees of pants or the cuffs of sleeves face constant stretching.

Elasticity helps these parts withstand repeated stress, reducing tearing and extending the fabric’s lifespan.

For workwear or children’s clothes, which endure rough use, this durability is essential.

What Makes Doubled Yarn Better Than Single Yarn for Elastic Fabrics?

Doubled Yarn Stretches Further Without Breaking

Single yarns have a limit to how far they can stretch before snapping. Doubled yarns, with their combined strength and twisted structure, can stretch more extensively while maintaining their integrity—ideal for fabrics that need to accommodate movement.

This extended stretch range also allows for more form-fitting designs without sacrificing durability.

It Recovers Faster After Stretching

Even if a single yarn stretches without breaking, it may not return to its original length.

Doubled yarns, thanks to their spring-like twist, bounce back quickly, ensuring the fabric stays tight and well-fitted.

This rapid recovery is crucial for garments like waistbands or cuffs, where sagging would ruin the fit.

It Reduces “Bagging” in High-Tension Areas

“Bagging”—when fabric stretches out and stays loose—is a common issue in single-yarn knits.

Doubled yarns resist this effect, keeping areas like waistbands, collars, and toe boxes of socks snug and functional.

The twist’s tension acts as a memory, pulling the fabric back to its original shape after stretching.

How Does a Yarn Doubling Machine Improve Yarn Strength Alongside Elasticity?

Twisting Adds Tensile Strength to the Yarn

The twisting process compacts the yarns, making them stronger and more resistant to tearing.

This means the fabric can be both elastic and durable—no need to sacrifice one for the other.

The compacted structure also reduces the risk of fraying, a common problem in single yarns with loose fibers.

Combined Fibers Resist Abrasion Better

Single yarns can fray when rubbed against other surfaces. Doubled yarns, with their twisted structure, create a smoother, more resilient surface that stands up to friction, preserving both elasticity and strength.

This is vital for items like backpack straps or sofa covers, which endure constant rubbing.

In testing, doubled yarn fabrics show up to 30% less abrasion damage compared to single-yarn counterparts over time.

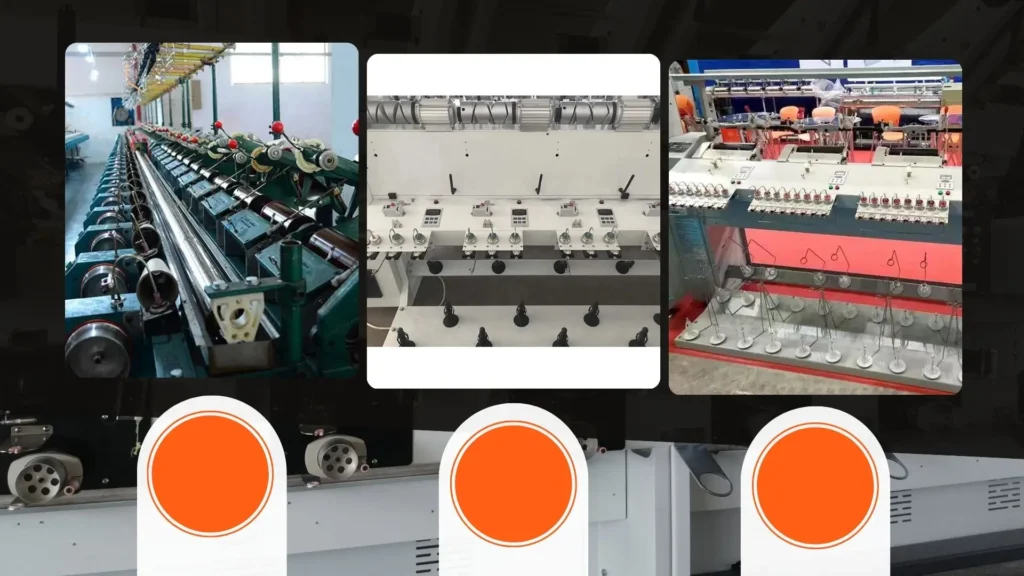

The Machine’s Controlled Twisting Prevents Overstretching

Yarn doubling machines allow manufacturers to control the tightness of the twist. This precision ensures the yarn is strong enough to resist breaking while still retaining the flexibility needed for elasticity.

This control eliminates the guesswork, ensuring each batch of yarn meets exact strength and elasticity standards.

Can a Yarn Doubling Machine Work With Different Types of Yarn?

It Handles Natural and Synthetic Yarns Effectively

Whether working with cotton, polyester, or blends, yarn doubling machines can twist most types of yarn. This versatility makes them useful for creating elastic fabrics across a range of materials, from soft cotton loungewear to durable synthetic activewear. Natural fibers like wool, which can be brittle alone, gain flexibility whentwisted with a synthetic yarn, creating a balanced fabric that’s warm yet stretchy.

It Adapts to Different Yarn Weights and Thicknesses

From fine yarns used in lightweight shirts to thicker yarns for sweaters, the machine can adjust to various weights.

This adaptability ensures that even heavier yarns gain elasticity without losing their structure.

The machine’s adjustable tension settings prevent thinner yarns from breaking and thicker ones from bunching during twisting.

It Enhances Elasticity in Blended Yarns

Blended yarns (like cotton-polyester mixes) often need balanced elasticity.

Cotton adds softness, while polyester adds durability; when doubled, the twist ensures both fibers work in harmony, avoiding the “stiffness” of pure polyester or the “over-stretch” of pure cotton.

This balance is why blended doubled yarns are popular in everyday clothing like t-shirts and jeans.

How Does the Twisting Process in Doubling Machines Affect Fabric Quality?

It Reduces Pilling in Knitted Fabrics

Pilling—those small balls of fiber that form on fabric surfaces—happens when loose fibers rub together.

Twisting yarns tightly locks fibers in place, reducing pilling and keeping the fabric looking newer longer.

This is a major advantage for luxury textiles, where pilling can make even expensive garments appear worn.

It Creates a Smoother Fabric Surface

Doubled yarns, with their uniform twist, produce a smoother knitted fabric. This not only improves appearance but also reduces friction against the skin, enhancing comfort in wearable textiles.

For sensitive skin, such as in baby clothes, a smooth surface prevents irritation that can occur with the rough texture of single-yarn knits.

The smoothness also makes the fabric easier to dye evenly, resulting in more vibrant, consistent colors.

It Ensures Consistent Elasticity Across the Entire Fabric

Inconsistent elasticity can lead to uneven stretching—like a sleeve that stretches more than the torso.

The doubling machine’s controlled twisting ensures every part of the yarn has the same elasticity, resulting in uniform performance across the fabric.

This is critical for garments with structured fits, such as suits or dresses, where uneven stretch would ruin the silhouette.

Is a Yarn Doubling Machine Cost-Effective for Manufacturers?

It Reduces Waste From Weak or Inconsistent Yarns

Yarns that are too weak or uneven often lead to defective fabrics, which are wasted.

Doubling machines strengthen and uniformize yarns, cutting down on waste and saving materials.

For a medium-sized textile factory, this can reduce material waste by 15-20% annually, translating to significant cost savings.

It Improves Production Efficiency

Fabrics made with doubled yarns are less likely to snag or break during knitting, reducing downtime in production.

This efficiency speeds up manufacturing and lowers overall costs.

Over a year, this adds up to hundreds of extra production hours.

It Enhances Product Value for Buyers

Fabrics with better elasticity and durability are more appealing to customers, allowing manufacturers to command higher prices.

The machine’s investment pays off in higher-quality, more marketable products.

Consumers are often willing to pay a premium for clothes that retain their shape and last longer, making doubled yarn fabrics a competitive advantage.

What Should Buyers Look for in a Yarn Doubling Machine?

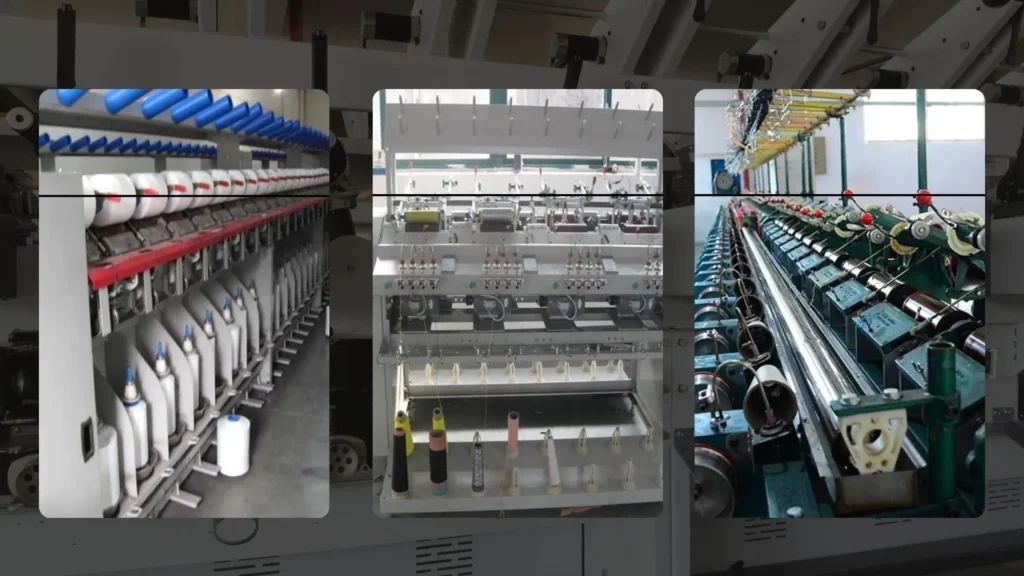

Adjustable Twist Settings for Versatility

A good doubling machine allows users to adjust the tightness of the twist, adapting to different yarn types and elasticity needs.

This flexibility ensures it can handle a range of fabrics, from slightly stretchy to highly elastic.

Look for machines with digital controls for precise twist adjustments, as manual settings can lead to inconsistencies.

User-Friendly Controls for Consistent Results

Complex machines can lead to errors in twisting. Look for machines with simple, intuitive controls to ensure consistent twist quality, even with less experienced operators.

Features like touchscreen interfaces and error alerts reduce training time and minimize mistakes.

Durability to Handle Continuous Use

Manufacturing environments are busy, so the machine should be built to withstand long hours of operation.

A durable machine reduces maintenance needs and ensures reliable performance over time.

Key components to check include heavy-duty gears, rust-resistant frames, and high-quality motors—all designed to handle 24/7 operation.

Also Read:

- How to Ensure Quality When Purchasing CNC Winding Machines

- 6 Common Mistakes When Sourcing CNC Winding Machines

- Discounts on Large Quantities of Yarn Doubling Machines

Conclusion

A yarn doubling machine is a valuable tool for manufacturers aiming to enhance elasticity in knitted fabrics.

This process isn’t just about combining fibers; it’s about engineering fabrics that adapt to real-world use, whether it’s a pair of leggings stretching with every stride or a sweater retaining its shape through countless wears.

For buyers looking to invest in equipment that delivers consistent, reliable results, a yarn doubling machine is a smart choice—one that bridges the gap between functionality and quality in knitted fabrics.

In an industry where fabric quality directly influences brand reputation, this machine proves to be more than just a piece of equipment; it’s a cornerstone of excellence in textile manufacturing.