The core strategy behind importing a single spindle winding machine from China is expanding the manufacturing ability.

There are many things to consider, beginning with important elements such as assuring product quality, supplier reliability, shipping logistics, and many more, before taking the plunge.

This detailed guideline will take you through all the key things you must know before you import a single spindle winding machine from China.

Let’s delve into essential documentation, common mistakes to avoid, why you must verify your suppliers, understanding the market landscape, shipping and logistics concerns, conformance with customs, and how to develop good risk management.

7 Things to Consider

Quality Standards and Certifications

One of the quality standards the equipment should meet for importing a single spindle winding machine is confirmation from suppliers of compliance with international standards—proof can be offered by suppliers holding ISO, CE, or UL certifications.

This helps ensure the reliability and safety of the machine.

Market Demand Analysis

Create a research about the target market and find out the major applications or industries that use single spindle winding machines.

Also, gain insight into demand trends, prevalent in the current scenario, current customer preferences, and the level of competition that exists in the target industry to make a wise buy.

Supplier Reliability and Reputation

Potential suppliers should be fully investigated in their background, references, and other online reviews.

A good reputation shows reliability and an increased chance of quality and good service after the sale.

Pricing and Cost Considerations

Pricing and Cost Considerations: Consider the base price of the machine plus the cost of shipping, import duties, taxes, and other charges.

Understand all the financial implications to prevent unforeseen charges.

Shipping and Logistics Options

Evaluate the various shipping modes: is it airfreight, sea freight, or consolidated versus time for delivery, budget restrictions, and machine size and weight.

Make a deal with your supplier on logistics to ensure that the arrival of your shipment is on time and within budget.

Customs Rules and Duties

Gather the most recent data about the import rules, customs process, and relevant duties in the country of destination.

If you comply with these regulations, there will be no delays and additional expenses while clearing your goods at customs.

Possible Problems/Associated Risks

Look for potential risks like quality problems with the products, disruption of the supply chain, or a change in trade policies.

Appropriate contingency planning should be done to mitigate such risks during the importation process.

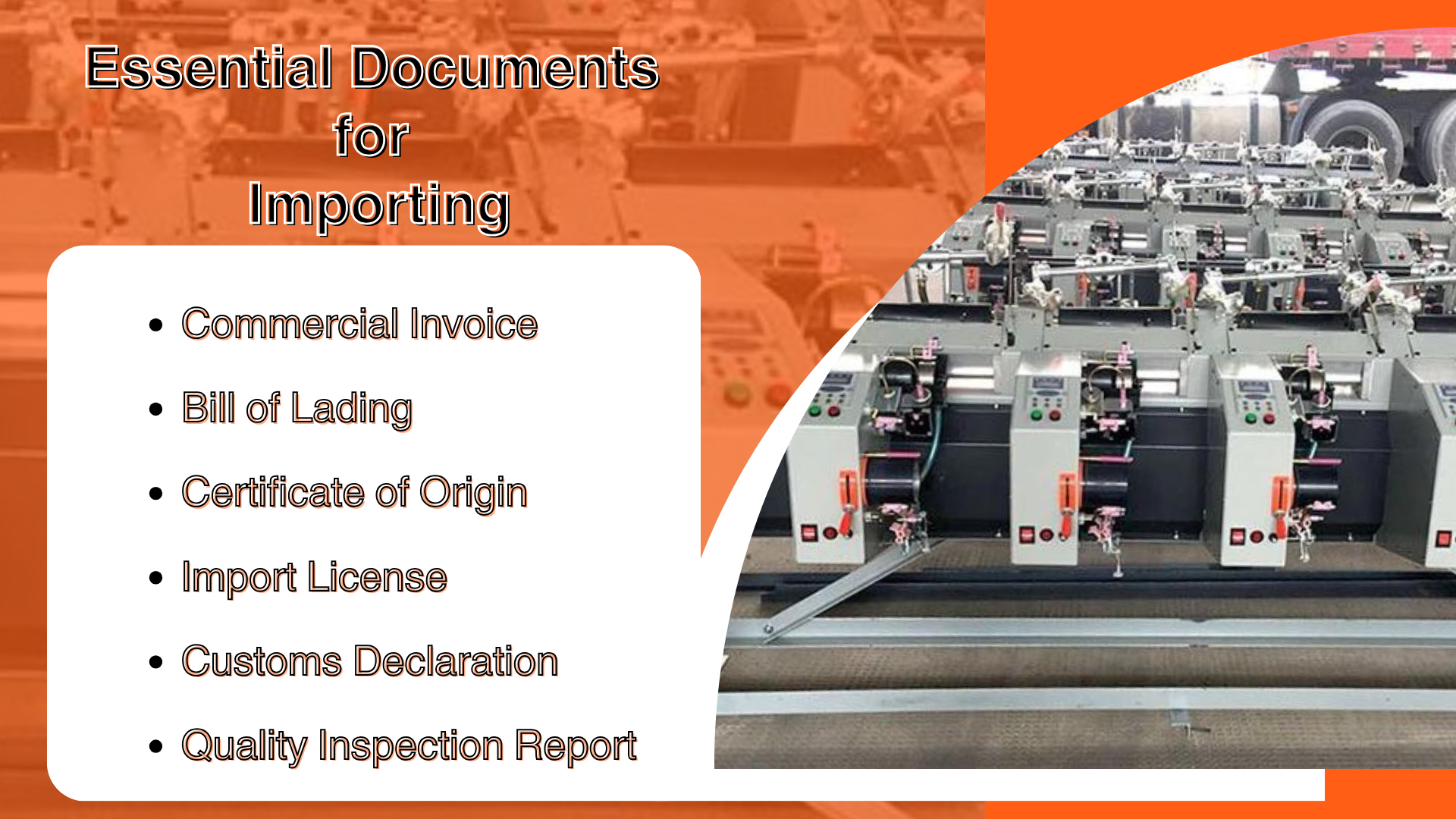

Essential Documents for Importing

The following is the detail of the basic documents required for the importation of the single spindle winding machine from China:

Commercial Invoice

A commercial invoice is an official document with transaction specifics, providing not only information about the buyer and seller but also a description of the goods, quantity, unit price, and total value, and the terms of sale.

It is important that the commercial invoice is correct and follows all the regulations concerning import, and this might result in some holds or delay during customs clearance of the shipment.

Read More:How Long Does It Take to Import Single Spindle Winding Machine from China?

Bill of Lading

The bill of lading describes shipment in detail like goods, origin, and destination, method of shipment, and mode of transport.

This form is important for the identification of location and status of the shipment, for claiming the goods when they arrive.

An individual has to ensure they get the right type of bill of lading which may be ocean, air, or truck, depending on the means of transportation that suits them.

Certificate of Origin

Import license, in this case, is the legal paper that positively determines what country the imported merchandise was produced or manufactured.

Customs may use this certificate to determine the necessary tariff or whether the merchandise is entitled to trade agreements or preferential treatment.

Thus, the verification of the certificate of origin and its contents are of significant importance to prevent issues during the customs clearing process.

Import License

Depending on the nature of the single spindle winding machine and the country’s import regulations, one might be required to get an import license.

The license allows one to import the goods because it gives permission by the authorities to allow the importation.

One should, therefore, do research and acquire the relevant and necessary import license where applicable to facilitate and ensure adherence to the law without delays or any further penalties.

Customs Declaration

Customs Declaration is a document that may be used to declare goods to Customs. It usually comprises the description of goods, value, country of origin and applicative, or other applicable tariffs and charges.

Fulfilling customs declarations accurately is a key requirement of a smooth customs clearance process.

Quality Inspection Report

Third-party inspection will confirm in a quality inspection report the quality and specifications of the imported single spindle winding machine.

This will go a long way toward assuring that the product will conform to the required standards and the buyer’s expectations.

A quality inspection report will serve to reduce risks associated with possible substandard or defective equipment.

Common Mistakes to Avoid

Following is the detail of common mistakes to avoid in case of importing a single spindle winding machine from China:

Failure to Properly Research the Supplier

Rushing into a supplier relationship without thoroughly vetting their capabilities, reputation, and reliability can lead to major problems down the line.

It’s crucial to conduct extensive research on potential suppliers, check their track record, and verify their ability to consistently deliver quality products that meet your specifications.

Ignoring Quality Control Measures

Not considering strict quality control implementations, pre-shipment inspections, and testing might introduce to the factory a defective or sub-par equipment, which in turn may not only cost you in terms of lowered production but also in the form of expensive repairs or the need to return the goods.

Underestimating Shipment Costs

This also involves shipping, where the shipping costs for the single spindle winding machine come with unforeseen expenses and budget concerns.

Such costs, not limited to but including freight, insurance, customs duties, and prospective storage charges, must be accounted for in budget planning accordingly.

Failure to Learn About Importation Regulations

Lack of understanding of the import regulations, documentation requirements, and customs procedures in your destination country can lead to heavy delays, additional fees, or even the rejection of the shipment.

You need to thoroughly research the import legislation and regulations that apply.

Ignoring Contracts

If there is missing such a clear and inclusive contract, misunderstandings or disagreements may settle in with the supplier and finally a legal tussle may be witnessed between the two.

Miscommunication with Suppliers

Ensure that the contract includes everything important: product specifications, terms of delivery, payment, and dispute resolution mechanisms.

Poor supplier communication can result in different or unexpected results and delivery delays, among other issues. Communication must be open and timely, and a process established to deal with any problems.

Failure to Factor in Possible Delays

In some cases, your production schedule might be disrupted due to unexpected customs clearance, disturbances in shipments, or any other problems that suppliers may have in production.

Keep alternative plans in place and include time buffers in your import timeline to ensure room is available for such unexpected delays.

Poor Risk Analysis

That way, a business can make a lot of losses both in terms of money and time, not identifying and cushioning itself against that kind of risk in the import process, due to things like currency fluctuations, political turmoil, or changes in trade policies.

Relying Solely on Price without Considering Quality

While cost is important, choosing the lowest price but without regard for the quality of the single spindle winding machine and reliability of the supplier may lead to getting less effective machinery which in the future may need some costly repairs or replacement.

Not Seeking Professional Advice When Needed

Any attempt to import a single spindle winding machine without the help of professionals, including customs brokers, logistics professionals, and legal advisors, can cause huge losses and take you into the compliance zone.

The Importance of Supplier Verification

Suppliers need to be verified for their reliability and credibility in importing a single spindle winding machine from China. The following details are of the primary ones to be taken care of:

Ways Suppliers Are Checked

Make sure you will have done your research about the potential suppliers, and you can have assurance of their trustworthiness and credibility.

Look into their references, past performance, and customer feedback; visit their actual production facilities; and do due diligence on their financials and legal compliance.

Use Third Party Inspection Services

The use of a well-known independent inspection company that verifies the specifications and quality of the single-spindle winder machine you wish to purchase can provide one more layer of assurance.

Their professionals can perform in-depth on-site inspection, testing, and quality checks to verify that the machinery fully complies with all of your requirements before it is sent to you.

This may alleviate receiving substandard or defective items, which could cause expensive delays, repairs, or a complete rejection of the delivery.

Building Strong Collaborative Supplier Relationships

Through open communication, trust, and shared expectations, you can work through many of the problems that may occur with importing.

Better responsiveness, better pricing, and a possibility of being on the front burner for the newest technologies are among other benefits from the supplier.

Understanding the Market Landscape

Before importing a single spindle winding machine, it would be highly important to understand the market and here are the key steps to consider.

Analysis of Market Trends

This would be information researched regarding aspects like project industry growth, technological changes in the industry, changing customer needs, and new market dynamics.

Knowledge of a larger market context will help you make an informed choice about the type of machine to import, its features, and the potential demand for these features in your target market.

Determining Target Customers and Industries

This could be in terms of creating a profile and assessment of the needs and pain points manufacturers, industrial facilities, or other potential end-users might have.

Knowing exactly the specific applications, production requirements, and points of irritation for your target market will allow you to match machine functionalities and features to your prospect needs.

Competitive Analysis

Basically, this will involve research into the features of the machines and prices at which they are offered by other suppliers, both in the country and abroad, in addition to their market share and feedback from the customers on their machines.

This will enable an identification of the gaps in the market, provide the machine’s capabilities with a unique value proposition, and enable identification of what price and positioning can best work to give you a competitive advantage.

Navigating Shipping and Logistics

The shipping and logistics management is quite important when importing one single spindle winding machine.

Some of the key elements in this area include:

Selection of the Appropriate Shipping Method

Air freight delivers much quicker but generally comes at a higher cost, while sea freight is much cheaper but takes relatively longer delivery periods.

Careful thought over your timeline, budget, and the urgency of the machine’s delivery will help you establish the most befitting means of freight transportation.

You can also consider factors concerning the size, weight, and fragility of the machine.

About Freight Forwarders

Freight forwarders facilitate logistics solutions relevant to importation that includes clearance, movement, and documentation.

The freight forwarder that you select should operate extensively in your target market and with the specific equipment that you are importing to help prevent probable issues and also navigate during the import process without any hitches.

Timelines for Deliverable Management

This needs to be coordinated closely with your supplier and freight forwarder to agree on a more realistic delivery schedule, account for potential bottlenecks or unforeseen events, and maintain a pro-active communication approach throughout the course of operations.

Applying contingency planning and buffer times, it allows for adaptation to the unexpected delays while ensuring that the machine will still reach your facility at the desired time, hence reducing the negative effects on your actual production and operational activity.

Compliance with Customs Regulations

Customs regulations must be adhered to since this will eventually avoid product delays or additional charges at the import.

So with that in mind, here are the key considerations:

Familiarize with Customs Procedures

This knowledge of the type of forms, permits, and declarations appropriate to a given type of importation and other import duties, taxes, or any other type of fees chargeable.

Understanding of the customs regulations will make it easy and quick to bundle through an importation venture with reduced possibilities of expensive delays and other risks.

Accurate Documentation

Keeping up with all the necessary documents, such as the commercial invoice, customs declaration, and other related documentation, updated, complete, and accurate is also very important.

Otherwise, clearances may become time-barred, extra charges may have to be incurred, or, in the worst cases, the shipment may be rejected.

Understand the Consequences of Non-compliance

This can be anything from levied penalties, fines, or even seizure of the consignment.

With very serious violations, one could actually face some legal implications.

Awareness of the risks and taking proactive measures to ensure compliance will also help you avoid issues that may be expensive and time-consuming once the import process begins.

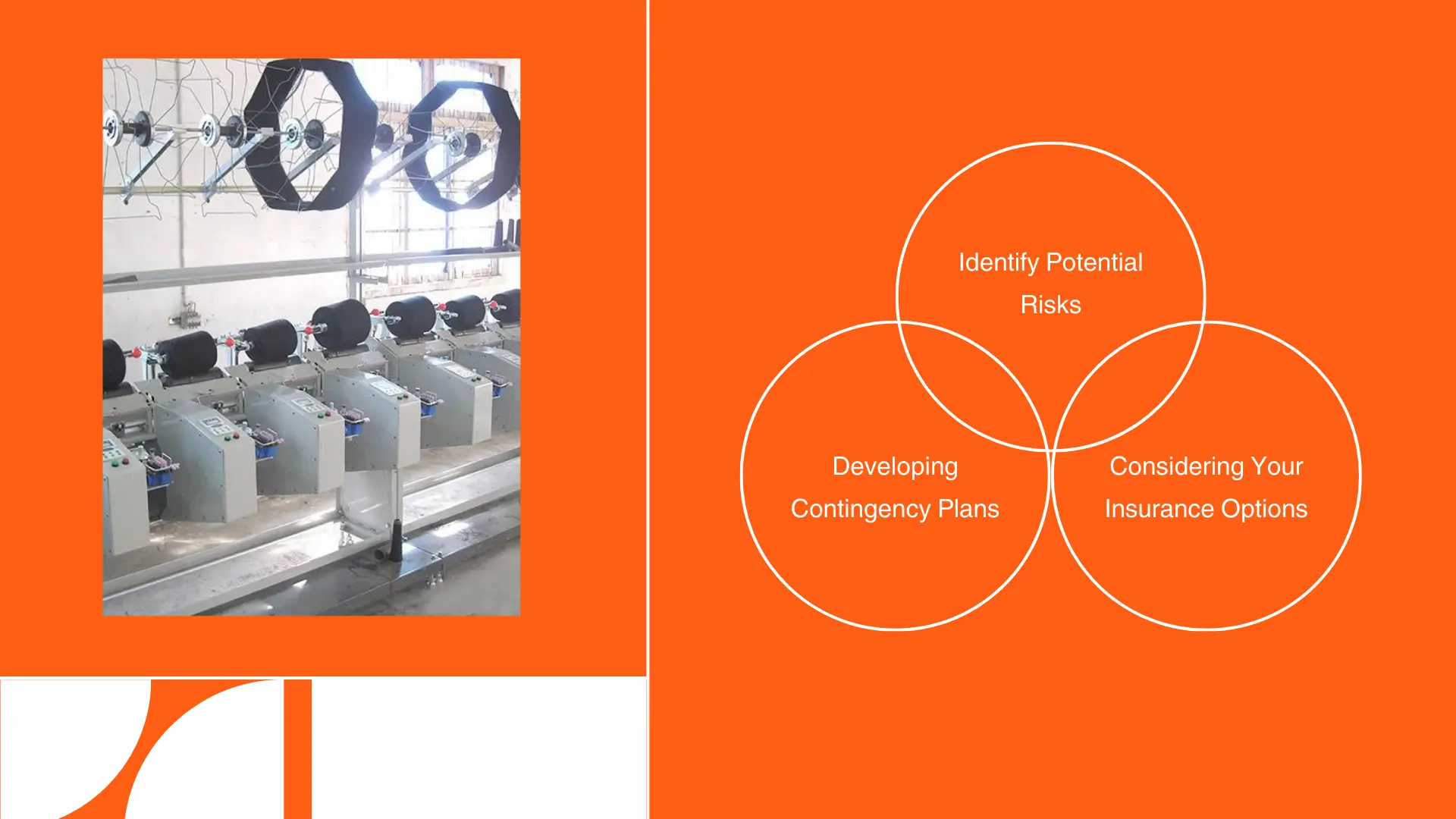

Risk Management Strategies

Having intentions of importing only one spindle winding machine from China to Uganda means that I have to note certain risk areas to carefully mitigate.

Here are the considerations to be made:

Identify Potential Risks

Full identification must be done on the potential risks that might happen in the course of importation.

This can vary from disruptions within the supply chain because of delays or shortages of the availability of the components/raw materials, quality issues with the machine itself, and changes in the trade policy and regulations laid down between China and the destination country.

By identifying these possible risks well in advance, you will be able to develop effective mitigation strategies against them.

Developing Contingency Plans

This can range from using backup suppliers, considering the implementation of quality control measures, or securing alternative transportation options.

With these many contingency plans in place, you can respond appropriately and promptly to all disruptions or challenges with minimal impacts on operations to ensure the timely delivery of the single spindle winding machine.

Considering Your Insurance Options

This may include cargo insurance to guarantee possible loss or damage during the process of shipping, and political risk insurance to cushion the effect of policy change and geopolitical events.

Assessing the right insurance will offer some extra safety and comfort throughout the import process.

Conclusion

Importing a single spindle winding machine from China is a venture that some people would highly consider.

Taking into account all the factors and appropriate planning, it is the way to go. Relating important factors, necessary documents, common pitfalls, and the related risk management strategies, go ahead and import that machine you need for business.