Buying a CNC winding machine is an important investment for any manufacturing company.

As technology advances, quality in such a machine would be highly regarded. This guide will provide the essentials of what to consider when choosing a CNC winding machine and make the process easier and more informed.

When you understand these key points, you will go ahead to make a purchase that improves your production ability and, ultimately, your bottom line.

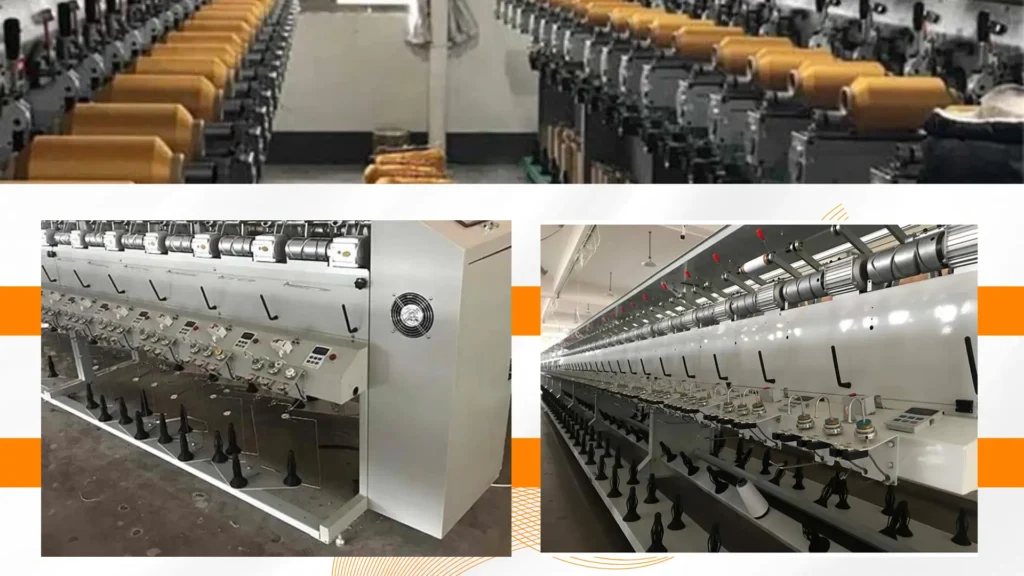

Product Recommend:

Understand Your Needs

Production Needs

Before even buying a winding machine, you should assess your actual needs in the production end.

What exactly do you intend to wind? Small designs with minute detail or bulky items?

Due to applications, you would require special winding techniques toroidal, helical or multi-layer windings for some cases.

Knowing your needs gives you an edge on the features you may need on the machines to be chosen.

Volume and Scale

Consider the volume of production you will have from the machine.

Are you a small startup with relatively low production, or are you a large manufacturer with high-volume requirements? Machines are designed for different scales of production.

If production demand is high, you may want a machine that will comfortably handle batches of high volumes; otherwise, a compact model will be good enough if your operations are considerably smaller.

In this regard, it makes sense that your choice should help to realize your operational goals and make the most out of your investment.

Research the Manufacturer

Reputation

The reputation of a manufacturer plays an important role in decision-making. Research companies within the industry for those that have a performance track record.

Generally speaking, an established company often speaks to reliability and quality since, throughout its life, the company would have built on its technology and services.

Awards or industry certifications may also be indicative of a reputable manufacturer.

Customer Reviews

Reading their customer testimonials and reviews will also be helpful in gathering data about the performance of the machine and the quality of service by the manufacturer.

See what comments are being said concerning the reliability of the machine, ease of use, and how responsive the customer support has been.

You can capture useful information from websites, forums, and social media platforms for similar users who have used this product.

Support and Warranty

Evaluate the type of support and warranty offered by the manufacturer. A good warranty is always comforting, as it helps you insulate your investment from defects or malfunctions.

Given that, consider if the manufacturer offers training along with on-going technical support.

That kind of support will prove to be highly beneficial in case you are a novice user of CNC technology so it will help you to understand the operation and maintenance of the machine.

Evaluate Machine Specifications

Technology and Features

Observe the technology and features involved in the CNC winding machine.

Advanced features included may be programmable logic controllers or integrated software for design and monitoring, which greatly enhance productivity and efficiency.

A number of machines are enabled to handle automation with them, saving labor costs by reducing human error.

While researching, align these technologies with your operational needs.

Precision And Accuracy

Precisions are critical in most winding applications.

Consequently, your machine must provide the level of precision that your application requires. Look for specifications describing tolerances and repeatability.

A machine producing high-quality and repeating accurate windings will improve your product quality and reduce waste, improving your reputation in the marketplace.

Flexibility and Customization

See how versatile the machine is in different types of projects. A machine easily adaptable for a variety of winding jobs saves on cost in the long term.

Flexibility will also provide the ease to adapt to the changing requirements of your customers or product lines without investing in new equipment.

Look out for machines that are capable of handing diverse wire sizes, materials, and winding patterns.

Ease of Use

Finally, consider the user interface of the machine and how it’s going to be easy to use.

An intuitively designed user interface can cut down on training times and overall boost efficiency.

Machines with touchscreen controls and intuitive software can simplify operation and let your team focus their energy on being productive instead of troubleshooting a complex system.

Assess Cost vs. Value

Initial Investment

Assess the upfront cost of the machine.

As much as it is very important to operate within the set budget, it is also quite important to consider the long-run value it will be able to deliver.

Sometimes, spending slightly more up front can lead to better performance and lower operating costs over time.

Comparison for similar models, with focus on which feature justifies the price difference, will give you the best value for your investment.

Operating Costs

Besides the initial investment, too, analyze the ongoing operating costs, including maintenance, energy consumption, and parts replacement.

A machine that is cheaper to run can make a big difference in profitability over its useful life.

Energy-efficient models, though more expensive to buy, could help save money on electricity bills.

Consider the availability of replacement parts and ease of maintenance, as these are factors to determine long-term costs.

Test Before You Buy

Request Demonstrations

Whenever possible, get a demonstration of the machine.

Sometimes it is possible to get more from a demonstration than from the description per se, about its performance and capability.

From live demonstration, one can sense the speed, precision and ease of operation of the machine.

This may well be a good time to ask questions and clear your doubts before you commit yourself.

Sample Production Runs

If possible, conduct sample production runs with the machine.

Such hands-on experience will give you an idea if the machine lives up to your expectations.

Testing it with your materials and specific production processes will make you aware of any problem areas and whether the machine is suitable for your operations.

Consider Future Growth

Scalability

Scalability: When investing in a CNC winding machine, consider its scalability.

As your business expands, so does the need to upscale or change your production.

You would not want to find yourself at some point being forced to purchase new equipment.

Where possible, seek out models that allow for additional features or attachments as your production needs grow.

Technological Advances

Keep yourself updated on emerging technologies in the field of CNC machining. Manufacturing is a continuously moving market; new inventions are entering the market every day, helping manufacturers be more productive and effective.

Consider a machine that can be upgraded to further versions or integrated with newer technologies to help your investment keep valid and working effectively for a longer time.

Market Trends

Monitor trends in your industry market. Knowledge of where the demand will likely head is sure to guide you into a choice of a machine that will serve your needs moving forward.

This would serve your business with a strategic competitive edge in the landscape and quickly make it respond to the change either at the level of the customer or by virtue of industrial standard.

Employee Training and Development

Finally, there is the matter of training and development of your personnel. A machine that is easy to use would lessen the learning curve for your employees.

On the other hand, a good investment in continuing training programs will enable your team to fully optimize such a machine and increase the productivity level on the whole.

Skill development will encourage not only your current operations but also prepare your workforce for the future.

Conclusion

Every manufacturing business should invest in a CNC winding machine.

If you know your needs, research the manufacturers, compare the specifications, evaluate the cost to value, and test the machine before buying, you will make a quality purchase.

Going forward with concerns for future growth will position your business for long-term success.

These steps will not only improve your production but help your business’s bottom line.

This weighed against informed decision-making will help you in the choice of a CNC winding machine that allows growth and success in the competitive manufacturing environment.