Small-scale CNC winding machines are the staple of many industries, ranging from electronics and automotive to renewable energy.

These devices represent a new generation in effectively making high-precision coils and transformers that play an indispensable role in modern devices.

As these industries are steadily pushing toward quality and speed, so is the demand for reliable winding machines.

Due to its solid manufacturing, China has become a leading supplier in the world supply chain for these machines.

Due to their novelty and affordability, Chinese manufacturers offer practical means for solving a wide range of business needs.

The article will further analyze the main actors of this area and provide an overview to potential buyers.

Learn More:

- Top 5 CNC Winding Machine Manufacturers in China

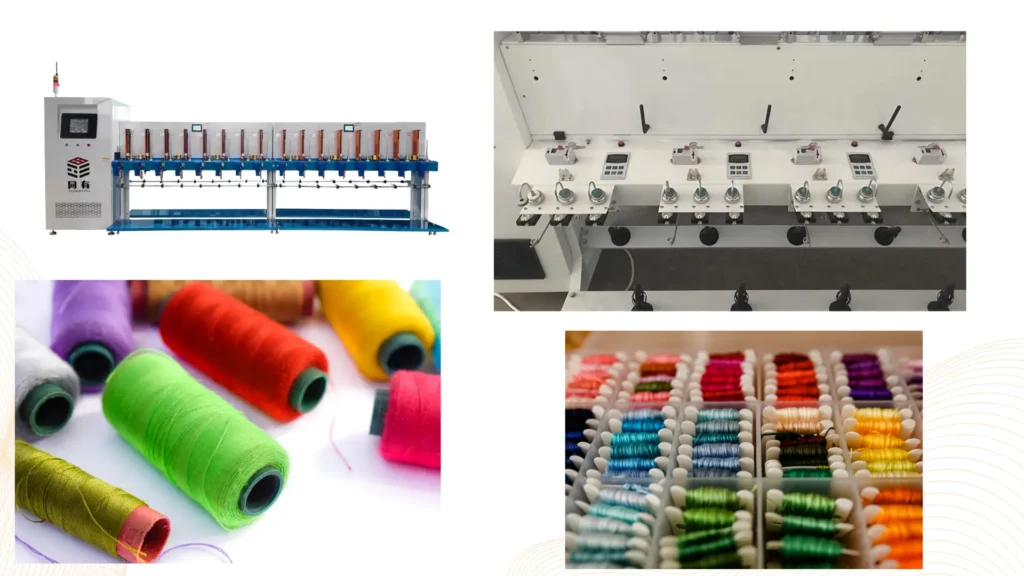

- Top 10 Yarn color card machine manufacturers in China

- Top 10 Textile Machinery Manufacturers in China

Leading Manufacturers

Below are a few well-known small CNC winding machine manufacturers in China, and each of them has its own characteristics and innovative features.

A few leaders in the sector are listed below.

Zhejiang Feihu Machinery Co., Ltd.

In 1995, Feihu Machinery Co., Ltd. was founded and has since been one of the innovative leaders in developing and producing textile machinery.

This focusing of efforts in renewing traditional textile production helped Feihu in the development of highly effective and energy-saving machinery, which practically improved the efficiency and quality of production.

1. Full Range of Products

From direct spinning machines, yarn doubling machines, to yarn expansion machines, and twisting machines, Feihu’s enormous manufacturing capacity serves industries and applications of all kinds.

2. One-Stop Solution Provider

Feihu is a one-stop solution provider from concept to finished products that allow customers to deliver effectively at less cost in terms of money and time.

3. Advanced Manufacturing Capability

Feihu has an experienced engineering team supported by fully equipped manufacturing facilities to ensure that delivered products will be of high quality, reliably performing.

4. Practicality and Easy Operation

Feihu fully aware that users prefer easy-operating equipment, has developed practical and convenient machines which could improve production efficiency.

5. High Standard of Quality Control

Feihu quality management system ensures stability and continuity to meet highly demanded market needs.

6. Continuous Innovation

For the last years, Feihu has been continuously introducing new models with superior features, step by step improving the limit of textile machinery technology.

7. Competitive Prices

The price of their products is far lower in comparison with foreign ones, but the quality is comparatively high.

8.Conformity to International Standards

Feihu always keeps pace with world development and never stops perfecting the machines for applicability, operability, and stability.

Wuxi Huake Machinery Co., Ltd.

Specialized in high-precision winding solutions, Wuxi Huake Machinery focuses on the automobile sector primarily.

Their machines are designed to reach the quality standard of this particular industry-so that each coil comes out consistent and reliable.

It is more keen on the issue of quality and hence gains priority among automobile manufacturers.

Shenzhen Wanshen Technology Co., Ltd.

Renowned for innovation and limit breaking, Shenzhen Wanshen Technology came up with machines that integrated automation and artificial intelligence.

Automation and AI make the production processes flexible, hence a great help for manufacturers in optimizing these processes.

Thanks to the integrated AI-powered analytics, users are able to track performances in real-time and perform decisions upon big data to improve efficiencies.

Dongguan Hengxin Automation Equipment Co., Ltd.

It is one of the renowned makers of cost-effective solutions that do not compromise on its quality standards.

A number of machines by Dongguan Hengxin include those which fit into any business firm that wants to improve its business production facilities without crossing its economic budget.

Their commitment to value has gained them a loyal following of customers.

Shanghai Shoujia Machinery Co., Ltd.

Heavy-duty machines are the factotum of Shanghai Shoujia, which pays close attention to durability and operating convenience.

All products are produced with full consideration of convenient integration into customers’ current production lines.

Ningbo Yinzhou Huachuang Machinery Co., Ltd.

This company lays more emphasis on offering custom solutions to fit the needs of an industry.

Innovation has made Ningbo Yinzhou Huachuang Company develop machines that fit the special requirements of different sectors for better performance and good production.

Guangdong Huaneng Electric Equipment Co., Ltd.

It believes in putting into practice the designing of various machines that consume less power without compromise on high performance with the growing emphasis on energy efficiency.

Their commitment to sustainability has thus appealed to environmentally conscious manufacturers.

Zhejiang Jinzhu Machinery Co., Ltd.

The company, now famous for its user-oriented approach in machine design, pays special attention to comfort and safety at work.

Its machines are designed with a number of safety features to make the workplace safe for operators.

Shenzhen Yituo Technology Co., Ltd.

It is highly recognized for its rapid prototyping capability to enable customers to rapidly test and put into practice new designs.

The agile production process of Shenzhen Yituo Technology is thus best for those enterprises willing to innovate and lead the competition.

Wuxi Yizhuo Machinery Co., Ltd.

Wuxi Yizhuo Machinery has carved its niche in the industry by offering excellent after-sales service.

It ensures serving a customer right from the installation of machinery to its life cycle.

The company’s customer-friendly approach has helped the company emerge as a reliable partner in the industry.

Comparative Review

A comprehensive comparison between the top 10 manufacturing companies brings to light a few important factors that buyers might find worth considering:

Product Offerings

Not all manufacturers specialize in the same products. Some specialize in a specific application, such as transformers or inductors, while others provide a wide range of machinery that could be applied to several industries. Knowing what you need will narrow down your selection of manufacturer.

Pricing Strategies

Pricing is a subjective consideration as it greatly differs from one manufacturer to the other.

Some manufacturers give high-level machines with greater capabilities, whereas other firms try to budget models.

It is crucial that you have aligned your budget with what you can actually use to avoid over-investment.

Customer Service

Customer support can also vary between manufacturers and may greatly impact your experience.

In general, companies that have a support team for training and maintenance services usually enjoy higher satisfaction ratings.

If you have a responsive customer service team, then you are guaranteed of prompt assistance in case of any issues.

Technological Features

Advanced technologies integrated into the winding machine can make them more user-friendly and maintain high efficiency.

Features like remote monitoring, automated setup, and programmable settings make the operation process easier and help increase the production output.

Selecting the Right Manufacturer

Selection of the right small CNC winding machine manufacturer involves careful examination of a number of factors that include:

Reputation

Manufacturer’s reputation is the most important thing in the industry.

Go for those with a proven history of supplying quality machinery with good customer service.

You can do this by looking up reviews and testimonials online about the reliability of any particular manufacturer.

Support and Training

Make sure extensive support and training for their machines are provided by the manufacturer.

This is somewhat significant for those who are new users who might need assistance in installation and operations.

A manufacturer with extensive training programs can get your team to high gear in no time.

Customization Options

Some manufacturers do provide special solutions devised to meet specific production needs.

If your business is one of them, then you must look forward to finding a manufacturer able to do so; this will ensure optimum performance for these machines.

Warranty and Service Agreements

Knowing what the warranty and service agreements entail will protect your investment.

A good warranty will protect you against defects or any problems with the machine.

Similarly, well-defined service agreements can assure you about ongoing maintenance and support.

Impact of Small CNC Winding Machines on Production Efficiency

The integration of small CNC winding machines has greatly revolutionized production processes in many fields.

Most their manufacturers consider such advancements and usually observe immense turnarounds in the effecting of efficiency and quality.

Improved Manufacturing Efficiency

Companies that have integrated the use of the CNC winding machines into their operations have greatly benefited from it by increasing their production capacities.

These types of machines ease processes and, thus, enable the company to respond timely to prevailing demand with the assurance of quality.

Improved Quality Control

The small CNC winding machines provide accuracy that decreases the chances of defects in the finished products.

It improves customer satisfaction and enhances the reputation of a company in the marketplace due to increased accuracy.

Innovations in Technology

Following are some of the recent technological advances that are being used to bring a change in small CNC winding machines:

Automation

Automation in manufacturing processes has completely changed the operation methodology of the winding machines.

Automated systems reduce the need for manual intervention, thereby reducing human error and increasing the throughput.

This helps manufacturers to scale their operations easily.

Integration of Artificial Intelligence

Artificial intelligence applied in the winding machines now enables real-time analysis of data and monitoring of performance.

This is where manufacturing companies can make better decisions for predictive maintenance, production scheduling, and optimisation of machine performance with the help of AI.

Market Trends

The market for small CNC winding machines is driven by a few key trends:

Sustainability

With growing environmental awareness within industries, sustainable manufacturing techniques are gaining more attention.

Manufacturers are also trying to align with greener design and operations that can even be efficient in resource usage and minimize generated waste.

Customization

With business trying to have an edge over their competitors in the market, the demand for customized solutions is on the rise.

This has led to more flexible options being provided by the manufacturers for enabling customers to modify machines as per individual need to extend productive capacity.

Challenges Faced by Manufacturers

Inspite of all their success, a few challenges are faced by small CNC winding machine manufacturers in China:

Competition

The market is therefore very competitive, and all the players attempt to take a large share of the market.

For relevance, innovation should be the center of any manufacturing company.

Companies should ensure that the set quality standards are observed, but also ensure market expansion into new territories.

Supply Chain Issues

The hitches in the supply chain can delay production or inflate the costs.

Diversification of suppliers and appropriate inventory management are some of the means through which the manufacturers try to minimize risks.

Conclusion

In simple words, choosing an appropriate small-scale CNC winding machine manufacturer decides the fate of any manufacturing organization.

It goes without saying that deep understanding of prominent manufacturers, consideration of influential factors, and analysis of recent developments in technology or market conditions basically help the organization draw better decisions to enrich their production capabilities.

The right choice enhances not only efficiency but possibilities for long-term growth and competitiveness in the industry.

This is, therefore, the very reason why it is necessary to invest in the appropriate type of winding machines, while the demand for high-quality, precision-engineered components increases, too.