Yarn doubling machines represent an important apparatus within the textile manufacturing industry.

These special machines can twist more than one strand of yarn together into one strand, making it more durable.

Their importance cannot be gainsaid since they enhance the quality and speed of producing yarn substantially.

We’d love to help you clear some of the mists around Yarn Doubling machines with some of the best options available in China and put together a guide for potential buyers looking to enhance their production processes without having to go back deeply into technical issues.

Learn More:

- Top 10 Yarn color card machine manufacturers in China

- Bulk Yarn Doubling Machine Imports from China

- Top 10 Textile Machinery Manufacturers in China

An In-Depth Review of the Top Yarn Doubling Machines Available in China

Top Machines End

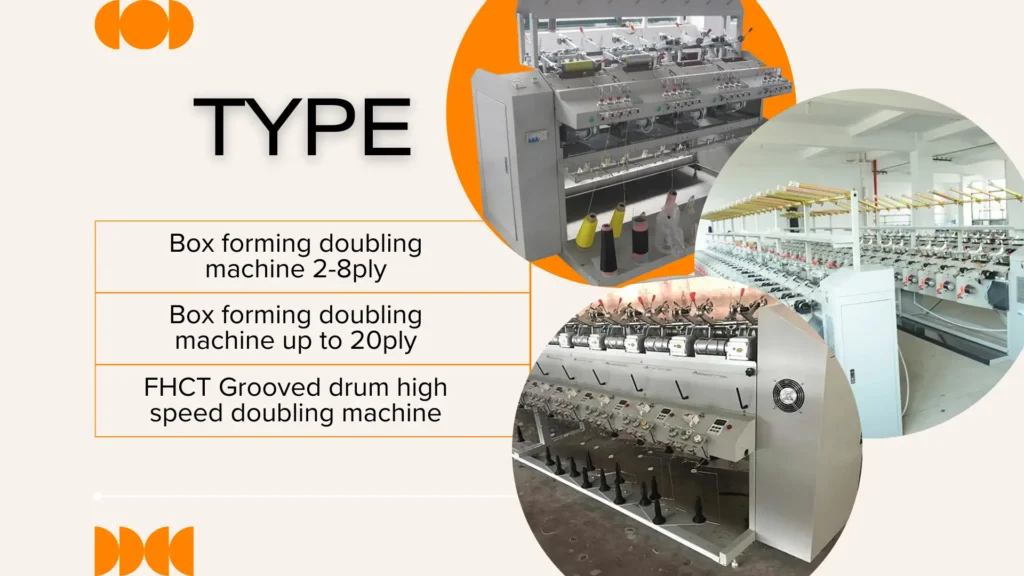

All kinds of advanced yarn doubling machines, which meet all kinds of production requirements, are available.

Some of the best ones include the TFO-2000, YD-6000, and the ZD-800.

Each machine type has special characteristics that enable various companies to better target certain specific markets.

Characteristics of Each Machine Type

TFO-2000

It is a high-speed yarn doubling machine with an automatic tension control function that maintains consistent quality in yarn, with high production output.

Advanced features make it more suitable for large-scale operations of the textile industry.

YD-6000

Advanced digital controls help YD-6000 to focus on energy efficiency and will be ideal for manufacturers concerned about sustainability.

This also calls for ease of operation as operators will easily change the settings whenever they would want to do so.

ZD-800

Compact and user-friendly, the ZD-800 is ideal for a smaller business or startup.

Yet, despite its small size, it provides excellent, consistent performance, creating good, quality doubled yarn.

Benefits and Comparisons

Comparing these machines, one has to remember that the TFO-2000 outpaces all others for sheer speed, but the YD-6000 is totally unique for its features and energy-saving capabilities.

The ZD-800, having a lower capacity, is much more affordable and simpler, which makes this machine a real competitor for any enterprise desiring to save on initial investment.

The Importance of Yarn Doubling Machines in the Textile Industry

Role of Production Efficiency

The yarn doubling machines make things easier by automatizing the twisting of yarns, hence reducing manual involvement.

This will reduce costs and save time.

Therefore, manufacturers can produce a large volume of yarn within a short period by increasing the volume notably. Consequently, it enhances efficiency.

Quality of Product

The high-quality products are ensured by constant tension and precision provided by modern yarn doubling machines.

More uniform twists in yarns reduce the possibility of fraying or breaking of yarn; this will also ensure that the final textile product can maintain high standards for durability and performance.

This way, the product ascertains quality, which is a vital component to satiate customers’ demand and retain the brand’s reputation.

Innovations from Chinese Manufacturers

Chinese manufacturers are still candid about yarn doubling machinery in terms of technology.

With constant research and development, machines not only came up for good performance but also started incorporating the factor of intelligent technology into their working.

This helps them maintain a good pace in the highly dynamic market.

A Guide to Selecting the Best Yarn Doubling Machine for Your Business

Things to Consider

There are a few critical things to consider when choosing a yarn doubling machine.

First, the capacity of the machine will need to be compatible with your production goals-you need to make sure that the model you buy can efficiently handle the workload.

Second, many critical aspects of such a machine’s performance and reliability may depend on its technology.

And lastly, the cost of the machine will need to include maintenance and operation costs so as to ensure the investment is worthwhile.

Recommendations by Business Size and Needs

Small-scale Businesses

In small-scale operations, ZD-800 is recommended on account of its compact design and affordability.

It is the best model for any startup to have good performance without having to invest excessively in buying the machine.

Medium to Large Enterprises

TFO-2000 or YD-6000 suits the needs of those businesses with a requirement of higher production.

The machines are designed with advanced features and a higher capacity, enabling big operations to be fully efficient in terms of output.

Tips to Make an Informed Decision

Read about different models by going through user reviews and user testimonials.

Consult with industry professionals or peers regarding machines that have served them effectively.

Always choose a scalable machine to grow with your business.

Exploring the Technological Advancements in Yarn Doubling Machines

Recent Improvements Overview

Recent development related to yarn doubling involves the addition of automatic tension adjustments and onboard monitoring systems.

These features facilitate correction on the spot, thereby increasing the speed of production while minimizing scope for error.

Performance Improvement through Technology

Application of smart technology further optimizes this performance of machines by ensuring efficient production, reduced waste, and better quality yarns.

For example, automatic machines that detect discrepancies in tension automatically adjust, hence promising a lot of consistency in output.

Future Trends in Yarn Doubling

Going forward, the industry is likely to witness further inroads into the integration of artificial intelligence and the Internet of Things in yarn doubling machines.

These will provide predictive maintenance that will ensure the machines operate at optimal levels with minimal shutdowns.

Case Studies of Successful Textile Businesses Using Yarn Doubling Machines from China

Examples of Businesses That Have Benefited

Quite a few textile companies have been able to introduce Chinese yarn doubling machines into their lines of production.

To illustrate that this machine is truly effective and reliable, one major manufacturer cited a tremendous gain in production after the integration of the TFO-2000 into their work scheme.

Machinery Involved and Impact Created

A medium-scale textile company shifted to YD-6000 and achieved a 30% enhancement in the efficiency of production.

This can be considered a good example of how adaptation to new and improved machinery may result in substantial operational advantages.

Lessons from These Cases

The most striking lesson that can be drawn from the case studies presented here is that high-priced machinery pays off in the longer run.

Enterprises that invest in latest technology have often tended to become efficient and cost-effective in production, with quality product, to hold their heads high in competitive textile markets.

Maintenance and Care for Yarn Doubling Machines

Importance of Maintenance

As yarn doubling machines are heavy machinery and perform critical tasks, proper maintenance is necessary for it to last and work efficiently.

If not serviced regularly, breakdowns may occur, which cause a lot of money and hinder the production process.

Tips on How to Keep Machines at Their Best

Establish a program for periodic inspection of your yarn doubling machines.

Clean the machines regularly to avoid an accumulation of dirt in them, and grease the machines with products recommended by the producers. This will also help in keeping your machine going without any hitch.

Common Problems and Remedies

General problems that one may face with a doubling yarn machine include thread breakages and uneven tension.

These are usually surmountable with the correct adjustment of the machine parts along with regular maintenance checks.

A maintenance logbook may be found useful to ensure that the emergence of any persistent problem may be solved well before it builds up.

Cost Analysis of Yarn Doubling Machines

Break Up of Initial Investment vs. Long Term Savings

High-quality yarn doubling machines could require a pretty high initial investment, but it is very important to consider long-term savings.

Better machines could imply better labor cost savings, lesser waste, and higher production rates, which are a pretty attractive return on investment.

Factors Affecting Pricing

Prices for yarn doubling machines vary depending on a number of factors, which include such aspects as technology applied, capacity, and brand reputation of the machine.

As such, higher-quality machines boast more features to warrant a price range, hence the importance of assessing what exactly matters to the business.

Return on Investment Considerations

To estimate the possible ROI, multiply the probable gain in productivity and quality.

This analysis will give you a more accurate idea of how long it is likely to take before you recover your original investment and enjoy its benefits.

Customer Support and Service from Chinese Manufacturers

Importance of Dependable Customer Service

In this vein, good customer service will always help resolve issues that may come up during the operation of the yarn doubling machine.

Good support can thus minimize downtimes and ensure production is minimally hampered.

Overview of Support Options Available

Most manufacturers in China offer on-site installation services, operator training, and packages for maintenance.

This level of support will go a long way in enhancing user experience and operational efficiency.

Experiences from Users

Customer reviews most of all include praise for responsive customer service.

And the positive experiences with support can reinforce a manufacturer’s reputation and persuade new buyers to take a second look at their machines.

Conclusion

Therefore, investment in a good-quality yarn doubling machine can be considered strategic for improving production capabilities within any textile business.

An understanding of the features, benefits, and selection criteria, as outlined in the blog post, will allow prospective buyers to make informed choices aligned with their business goals.

By embracing recent developments in yarn-doubling technology, businesses not only enhance their productivity but raise the quality of products, thus enhancing their competitive edge in the textile market.