The manufacturing world is slowly changing day in and day out.

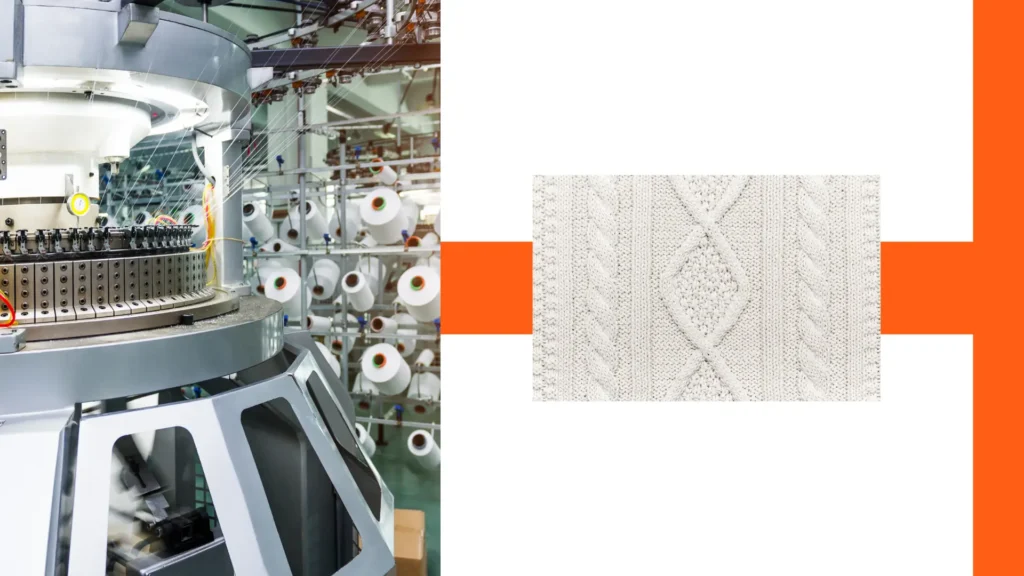

Among these, the use of Computer Numerical Control winding machines is considered to be the most important thing in the fabrication of quality electrical components such as transformers, inductors, and coils.

For investors in such machinery, sourcing from China can prove to be very advantageous.

This paper highlights seven key benefits one can reap from buying a CNC winding machine from a Chinese manufacturer and pinpoints the importance each will hold for the prospective buyer.

Cost-Effectiveness

Cost-effectiveness, which seriously affects the bottom line of a company, is one of the biggest selling points that come along when buying a CNC winding machine from China.

The capability of sourcing high-quality machinery at a competitive price will better position a business to direct their resources.

In fact, this cost advantage is very important for companies that look forward to maximizing their investment but minimizing the costs.

The reason is that by getting hold of the Chinese manufacturers, they can save a lot of their money to reinvest in other important areas of their business, like expanding

their product line or customer service-related initiatives.

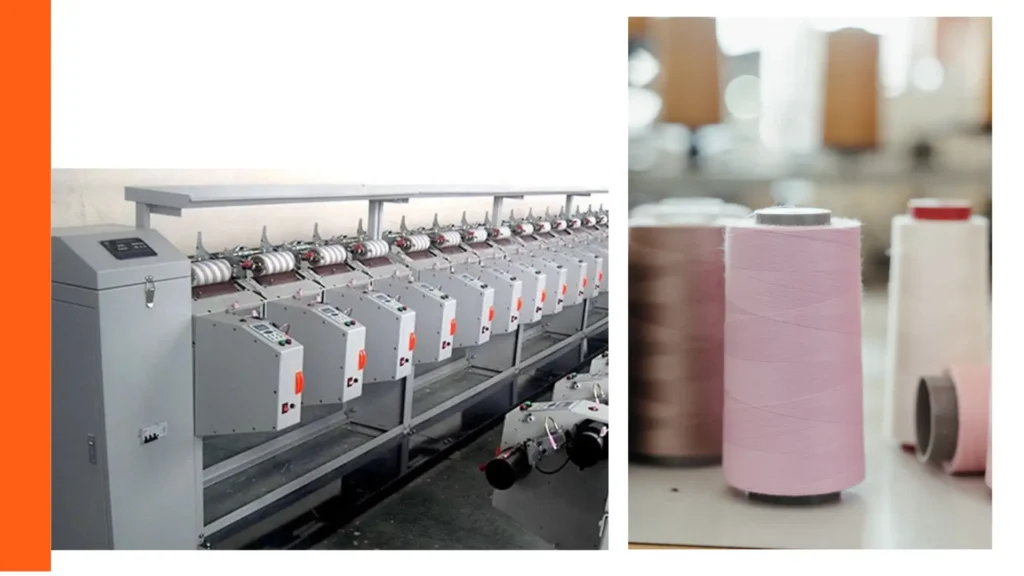

Low Production Cost

Chinese manufacturers enjoy manifold reasons for low cost production, which is essentially brought about by lower labor costs in addition to super-efficient production processes.

They are able to offer CNC winding machines at lower prices, but they do not reduce the quality of these machines.

The economies of scale gained from large-scale operations further make them price competitively.

This way, companies can access advanced machinery with desired functionality without necessarily denting their pockets. In this, businesses possess financial maneuvering abilities that will see to the enhancement of general profitability while remaining competitive in the market.

Cost-Friendly Alternatives

Companies with relatively smaller budgets consider sourcing their needs for CNC winding machines from China.

That provides access to quality machinery within the financial means of the companies. It further allows even relatively small companies to invest in high-quality equipment while improving production capabilities.

With the opportunity to save on machinery costs, money could be freed up to invest in other resources such as marketing programs or employee skills training, or additional research and development.

This has wide strategic implications for resource allocation that could spur growth and innovation, enabling enterprises to be agile and competitive in an ever-changing industry.

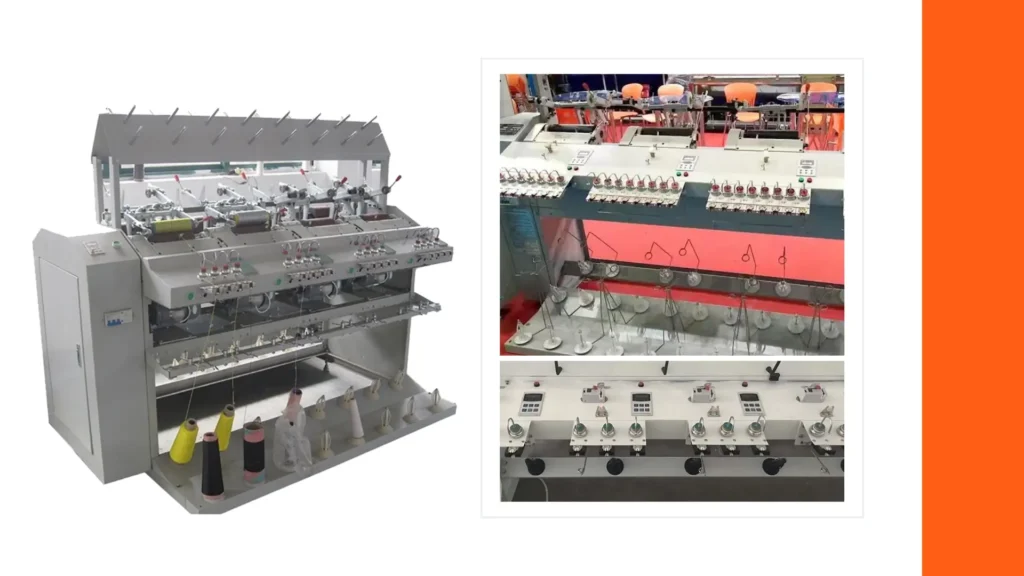

Product Recommend:

Advanced Technology

Chinese manufacturers have risen incredibly in technology and innovation, hence competing at the top in the market for CNC machines.

For this reason, they have sworn to adopt and develop advanced technology, making the machinery functional, efficient, and reliable.

This is evidenced by most of their advanced featured CNC winding machines, which are attractive to any company willing to increase its production process.

State-of-the-Art Features

Many of the CNC winding machines built in China are indeed fitted with state-of-the-art features regarding advanced technologies, including automatic controls and real-time monitoring systems that ensure precision winding.

Such advanced technological features mean a great deal to operational efficiency, implying high production at increased speeds, while immense accuracy in the winding processes is maintained.

The integration of such technology decreases errors, while product quality is improved and business operations are simplified.

This leads to an effective production environment that can easily adapt to demands and challenges thrown its way.

Continuous Improvement

The fact that many Chinese manufacturers attach a lot of importance with research and development creates a culture of continuous improvement.

In an ever-changing industry, with changing customers’ needs, modern and adaptable machinery is increasingly important for future success.

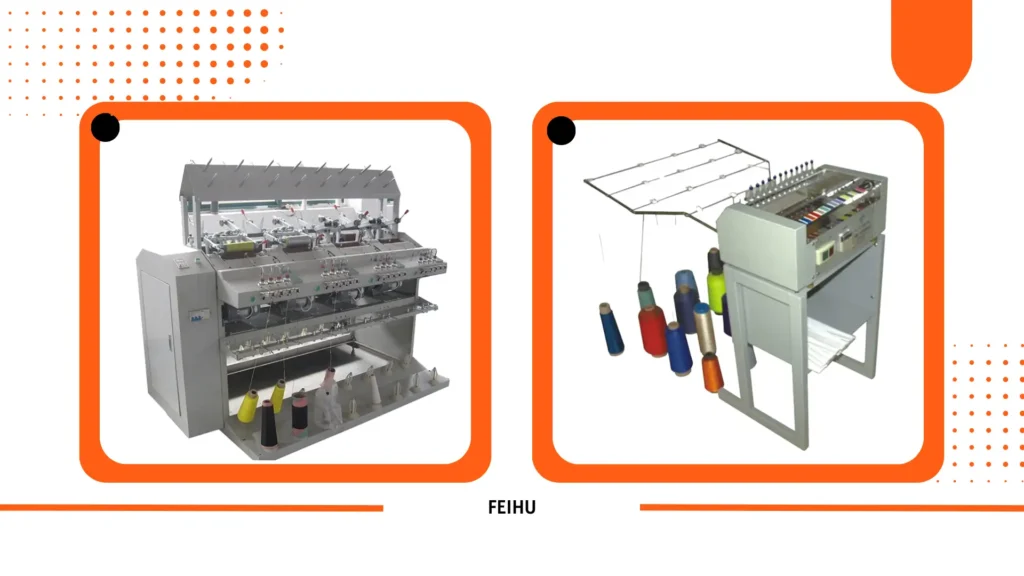

Wide Range of Options

The variety of the CNC winding machine market in China ranges from manufacturers who can suit the needs of various applications for businesses.

This wide variety will ensure that companies get the right equipment to fulfill their production requirements, no matter how big or minute.

The numerous choices will enable companies to opt for machinery compatible with their operational objectives and hence maximize their efficiency and output.

Variety of Models

With so many models available within the country, whether the company needs machinery for small-scale production or large industrial applications, it’s possible to tailor solutions.

This wide availability in offerings makes it easy on a business to find and buy machines that will meet their production volume and technical needs.

Such will be contributing to the workflow optimization of a company and meeting the demands of a particular industry.

Flexibility

Adaptability across various methods of production is also enabled because there are a large number of CNC winding machines available within the country.

Businesses can opt for machines offering various winding techniques for accommodating various types of coils and components.

This, in return, offers critical flexibility to those kinds of manufacturers who aim to diversify their product line or meet certain customers’ needs.

The selection of adaptable machinery allows a company to give priority to shifting market conditions by enhancing production capabilities.

Customization Opportunities

Most of the Chinese manufacturers are open to offering customization possibilities with regard to their CNC winding machines, which could prove to be one of the most transformational advantages for a business.

This flexibility allows companies to adapt machinery to special production processes, hence enabling the equipment to meet particular operational requirements.

The machine customization possibility enables not only more efficient production but also closer alignment with a company’s goals and strategies.

Customized Solutions

Companies can also have their CNC winding machines customized according to their pattern, size, and winding type.

By doing so, the machinery can become so well integrated into one’s workflow that it would be working in a most efficient way.

Companies may justify these investments because custom solutions help in rationalizing the manufacturing process by reducing overall waste and enabling effective operations that will have an advantage over the competition.

This level of customization really increases productivity and helps the bottom line.

Increased Efficiency

Investing in the right CNC winding machine for specific needs ultimately brings increased efficiency to processes.

With equipment designed for their particular demands, businesses can start streamlining operations to minimize downtimes and waste of materials.

Accordingly, with enhanced efficiency, not only does the production become more proficient, but better management of resources and cost-effectiveness will also be ensured.

All these perks put together in a competitive market surely promise to give your business an opportunity to stand out and grow.

Reliable Quality

While many would still argue otherwise, many of the Chinese manufacturers are now keen on quality assurance.

International Standards

Many of the manufacturers follow stringent international quality certifications.

1. Quality Assurance Procedures

Accreditations such as these ensure that machines maintain a higher standard of quality and performance, thus assuring buyers of their investment.

2. Durability and Longevity

A commitment to quality means that the machines will also be durable and can be relied upon, reducing significantly the chances of breakdowns and maintenance issues.

Positive Reviews

Researching or reading third-party review websites and customer comments in various forums regarding these companies will help buyers determine which of these are good manufacturers.

1. Customer References

Most companies showcase how well certain applications they have used were served by their Chinese-built CNC machines.

2. Standing of the Company in the Industry

Long-standing companies are assumed to have some sort of good reputation within the industry. This will surely assure other companies planning to invest in their machinery.

Reputation

Getting reputable manufacturer names is critical in researching for an assured positive buying experience.

1. Established Brands

Well-established brands can assist in mitigating the risk of quality and support. Recognized well-established manufacturers that through the time have provided successful products

2. Industry Partnerships

the fact that most of the established manufacturers have partnerships with global companies is a great indicator of their reliability in terms of quality

Strong After-Sales Support

One of the best benefits when it comes to buying from the well established Chinese manufacturers is the robust after-sales support.

Installation

Most of the manufactures provide extensive services in installation.

1. Professional Installation

Proper installation by professionals reduces the chances of operational problems right from the very beginning.

2. Time-Saving

With quick installation services, businesses can kick-start the production quite sooner and maximize machine uptime.

Training

Training is the most important feature of after-sales service.

1. Staff Training Programs

Most of the leading manufacturers provide your staff with training programs so that the operators on the site are properly prepared to work on such machines.

2. Operational Excellence

Well-trained personnel enhance operational efficiency and safety, contributing to a better production environment altogether.

Continuing Maintenance

The availability of maintenance services will prevent any possible issues from arising and give your machine a long life-span.

1. Preventive Care

The periodic checks for maintenance let the problems, if present, be sorted out at the very initial stages. This minimizes your downtime and preserves your investment.

2. Long Life of Machinery

By regularly updating your CNC winding machines, you will ensure that they work at optimal capacity and that you manage to squeeze out as much operational life from the equipment as possible.

Global Trade Networks

The trade networks in China are so well developed and intricate that importing machinery from the area can be done relatively easily and with very little hassle.

The international trade can prove seamless with structured systems of suppliers, manufacturers, and distributors in place.

This networked web helps enterprises find sources that can provide machines of high quality and also saves time and efforts that are usually required in searching for items overseas.

This way, organizations can discover a host of alternatives available to them that would match their needs and ensure the perfect machine availability.

Streamlined Logistics

Logistical infrastructure is well-established in China and greatly increases the speed of shipment procedures.

As a result, the distribution channels were effective, with developed transport infrastructure and specialized shipping services that line up perfectly in moving goods from the manufacturer to the end buyer.

This means, from the time a sale is made, the route from the factory to its destination is optimized for speed and reliability.

In this regard, businesses can be guaranteed that their CNC winding machines will arrive on time, thus reducing any possible downtime and quickening integration with production workflows.

This efficiency not only cuts costs but also improves general effectiveness in operations.

Faster Ramp-Up in Production

Reduced lead times on machinery acquisition directly translate to faster ramp-up in production capability.

Quicker access to the CNC machines means that the business can actually start their production processes sooner, hence responding more promptly to the market demand.

This agility is sure to be invaluable in today’s competitive arena, where the ability to adapt to fluctuating consumer preferences makes all the difference between success and not quite.

Because businesses can get their machines up and running faster, they are able to take advantage of new opportunities that present themselves, effectively streamlining production schedules and further improving their market positioning.

All this is because responsiveness allows them to steal an edge and grow profitably.

Conclusion

Your investments in the CNC winding machines within China will yield great benefits, including cost saving, the best technology, and full support.

With this in mind, it is very critical that you conduct appropriate research in the potential manufacturers to come up with those who will fit your standard of quality and service expectations.

The best decision you make will contribute to enhancing your production capabilities for increased business success.