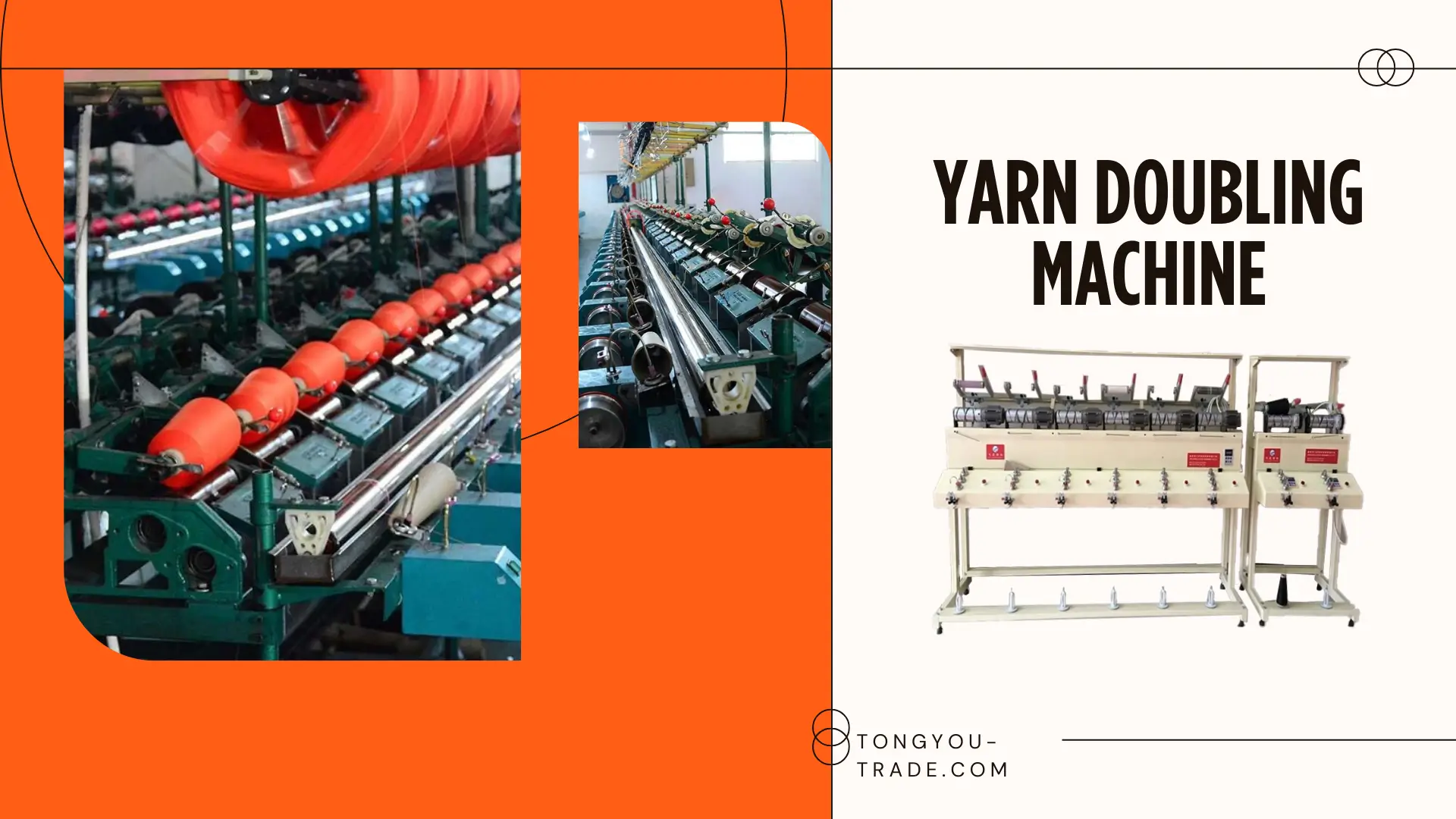

The process of selecting the yarn doubling machine can either optimize your production process and ensure quality products or otherwise.

You might find many choices over the yarn-doubling machine, but these also make it relevant to consider the key influence in your selection.

Here is the breakdown of the most crucial factors that may occur in making a decision.

Yarn Type and Count

Compatibility

It is a necessary point that the machine you purchase must be designed to handle yarn types that you are using.

For example, cotton yarns can take up to synthetic fibers.

On the matter of specifications, you will need to delve into the specifications of the machine you are buying in order to accommodate elasticity of yarn, its strength, and how well it retains moisture.

Considerations on Count

These various yarn counts influence the machine’s capabilities and functionalities.

A machine meant for finer yarns might not do well with thicker yarns, and vice versa.

Knowing the range in which yarn counts will fall in your production helps when trying to find machinery that can work with different materials without giving up quality.

Also Read:

- What Should U Know Before Importing Single Spindle Winding Machine from China?

- Single Spindle Winding Machine Advantages and Benefits

Production Capacity

Your production capacity requirement is one of the most important factors in the selection of a yarn doubling machine.

Because the doubling machine is capable of influencing overall output and efficiency, it will affect your potential to meet customer demands and stay competitive in the market.

Assess Demand

To decide which type of machine you should purchase, evaluate first your current and projected volume of production. This would include:

1.Current Production Levels

Take a measure of how much yarn you currently are producing and where along your process it gets bottlenecked.

This will provide a base understanding of your needs.

2.Future Growth Projections

Consider market trends, customer orders, and seasonal variations that may affect demand. In case you foresee more orders or seasonal highs, you should allow for a machine capable of handling such fluctuations.

You may invest in a machine with higher capacity than what you currently need to help you prepare for your future growth and give you the ability not to miss any great opportunities.

Capacity Options

Based on your production needs, here is an appropriate one to choose from:

1.High Capacity Machines

This will provide you with scalability to increase production levels effectively to avoid compromised quality in case big orders start coming your way.

Most often, they are fitted with advanced features that help in enhancing speed as well as in reducing the incidences of shutdown.

This means that they shall be ideal for a fast pace in the production environment.

2.Smaller models

The price is usually lower, and floor space is lesser, which may make it more practical for relatively smaller operations.

These are also easier to handle, particularly by businesses who are still building up their production processes.

Capacity and Needs Balance

Capacity and balancing your actual needs is very key to avoiding over-investment.

Overestimation may result in unnecessary expenses, while underestimation may lead to missed opportunities and hurried production.

This looks into how you can balance the following aspects:.

1.Modularity

Consider those machines that can be bought featuring modular or scalable characteristics in order to make it easy to increase the capacity of your machine when needed.

This allows you to buy a machine that meets today’s needs and be able to upgrade or add capacity at a later date without needing to replace an entire system.

2.Periodic Reviews

From time to time, go through your production rates against the market demand.

This will help you readjust the machinery choice over time to ensure that you can be flexible to the changed needs.

Also Read:

- Top 5 CNC Winding Machine Manufacturers in China

- Price Comparison of Yarn Doubling Machine with Others

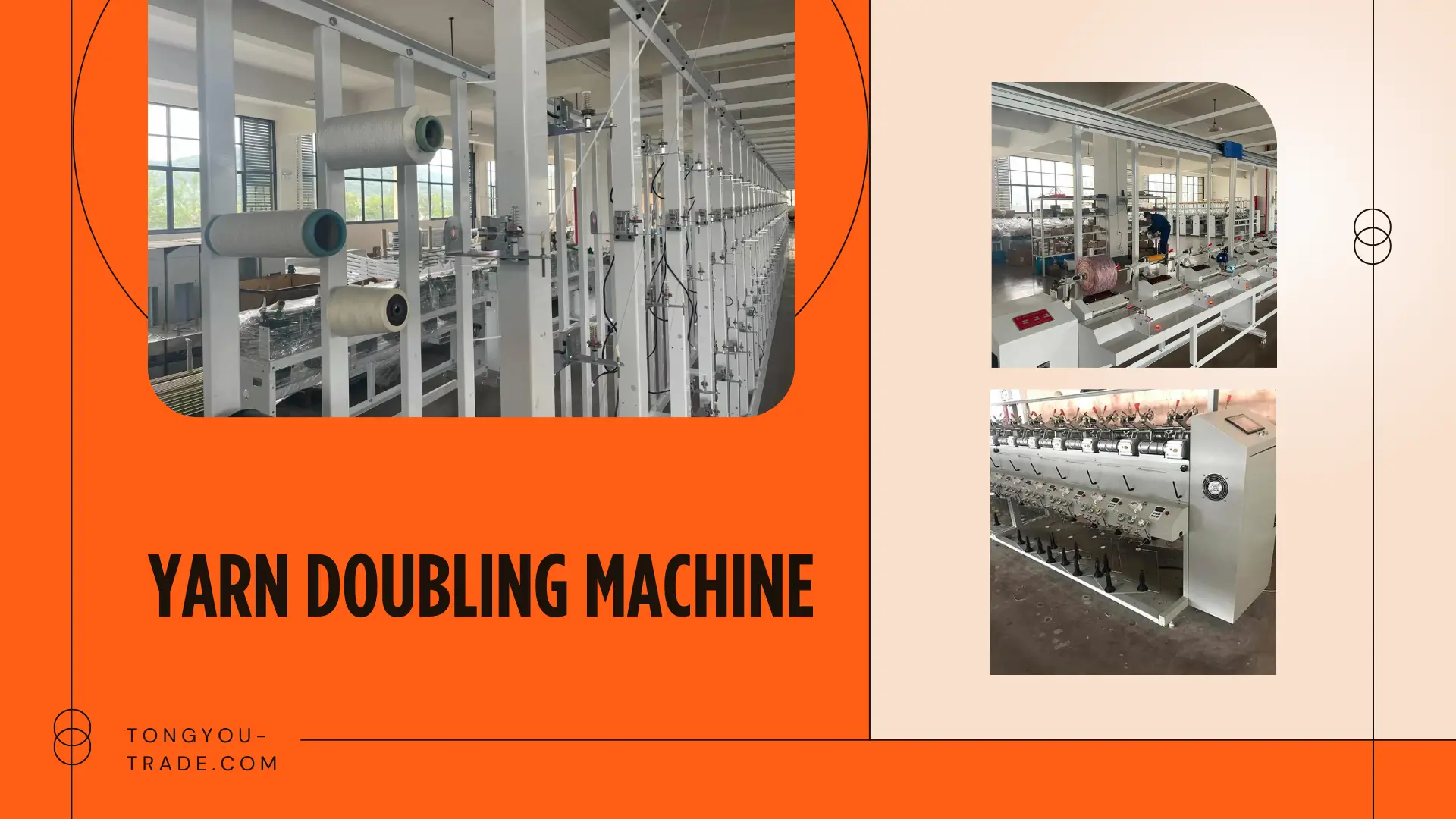

Machine Size and Space Required

Actual dimensions of the yarn doubling machine and the space availability at your facility is again another important factor.

You must know for sure that your workspace is large enough to fit the machinery for easy operations.

Measure Workspace

Measure your production area carefully before buying so you can be sure that it will fit comfortably.

This not only includes space for the machine itself but also space necessary for operators to work safely around it.

Layout Planning

Consider the overall layout of your facility, such as for maintenance access and material flow.

A well-planned workspace will increase productivity by ensuring ease of moving yarn and finished products within the facility.

Efficient layout will reduce waste and lost time to a minimum.

Cost and ROI Analysis

One must take into consideration initial costs as well as operating costs to determine the total investment required.

Make an Analysis of ROI

Calculating the return on investment helps state how quickly the machine is able to pay for itself from efficiency gains and reduced operational expenditure.

When calculating possible ROI, consider things such as labor savings, increased output, and decreased material waste.

Long-term Savings

While it may be daunting because of the higher initial cost, the justification could be in performance and reliability over time.

These machines assure significant long-term savings by cutting costs through decreased maintenance and reduction in production disruptions for added features or improved durability.

Also Read:Discounts on Large Quantities of Yarn Doubling Machines

Additional Features and Customization Options

Many new generation yarn doubling machines boast a number of value-added and convenient additional features to this operation, such as programmable setting and automatic controls that contribute significantly towards increasing operational efficiency.

See Feature

Advanced technology reduces manual interference and enhances precision and efficiency.

Other additional features include automatic tension control, friendly user interfaces, and real-time monitoring to further enhance productivity based on simplicity of operation.

Customization

Look for machines whose functions can be tailored according to your particular production requirement.

Be it setting options according to yarn types being used or adding some specific functions, customizing your machine will guarantee competitiveness and more versatility in production.

Conclusion

Various factors are to be considered while investing in a yarn doubling machine, which involves yarn type, production capacity, space availability, cost involved, and additional features.

Comparing these various features will give you insight into making the best investment decision that works perfectly for meeting your production goals.

Taking this time will allow you to make the correct machinery selection necessary for proper quality and timely production of your products.