Single-spindle winding machines are specialty machines used in a variety of industries that wind wire, yarn, or other materials onto a core.

These machines are very instrumental in ensuring that production processes are accurately done with speed.

Having a single spindle, they work quite well on small runs of production or jobs that are specialized, hence ideal for companies in enhancing overall efficiency in operations.

Over time, China has evolved into a powerhouse in manufacturing, capable of producing high-quality machinery at much lower costs than most Western countries.

For this reason, importing single spindle winding machines from China gives the companies an opportunity to procure advanced machinery technology at considerably reduced machinery costs.

Cost-effectiveness improves profit margins and allows investment in other areas for business growth.

Learn More:

- Understanding Winding Machines – Definition and Types

- What Should U Know Before Importing Single Spindle Winding Machine from China?

- How Long Does It Take to Import Single Spindle Winding Machine from China?

Understanding Winding Machines

Definition

The winding machine is a mechanical device designed for winding wires or textiles onto spools or reels.

They ensure that the material intended for winding would be even and in place, something quite important in further stages of material processing.

It plays an important role in textile, electronic, and automotive industries, which largely depend on accuracy and reliability.

Types Varied

Winding machines vary in models, all suited for different needs at the production level.

Single spindle winding machines are suitable for smaller to medium-sized runs and provide more exactness and control.

Multi-spindle machines are designed for higher-volume production since they wind a number of spools at once.

This leads to understanding the differences in options so that businesses can select the right machine for their production requirements.

What You Should Know Before Importing

Key Considerations Before a Purchase

Assess your production needs before deciding to buy.

Consider the type of material that you will be winding, speed, and whether the machine will interface with existing equipment.

These considerations will lead you to select the right machine that suits your operation.

Researching Suppliers and Manufacturers

Identifying a good supplier is very vital in the process of importation.

In researching manufacturers, it is highly advisable to check their certifications, production capabilities, and customer reviews.

Such online platforms organize industry-specific trade shows to let your voice be heard and help you get in contact with dependable vendors.

Steps to Importing Single Spindle Winding Machines

Initial Research and Machine Selection

Seek preliminary information on various single spindle winders available in the market.

The basis of comparison in the course of this research needs to be specifications, features, and prices from different suppliers.

This phase of the research is very important because it helps you narrow down your options and invest in a machine that best suits your production objectives.

Contacting Suppliers and Negotiating Terms

After shortlisting the suppliers, contact them and ask for quotations and details.

Present your requirements clearly and negotiate on price, mode of payment, lead time, and warranty conditions.

Negotiating effectively will ensure better deals and more favorable terms for your purchase.

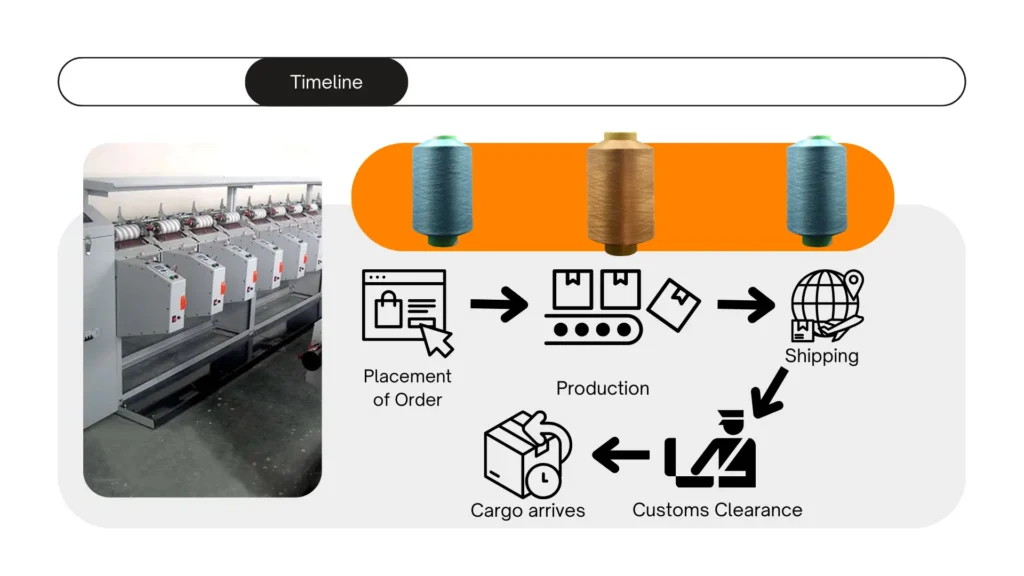

How Long Does It Take to Import?

Standard Time Required to Import Machines

Importing a single spindle winding machine can take anywhere between six to twelve weeks by general averages, placing the order to the actual arrival of the machine.

Of course, full understanding of such timelines will actually help you in planning your production schedules.

Factors That Can Affect the Duration

Several factors can be responsible for the realistic time frame that it may take to import, including manufacturing lead times, shipping method, and custom clearance procedure, among the most significant.

Manufacturing time is longer in peak seasons, so it will be best to keep such variables in mind while planning your import.

Product Recommend:

Steps to Understand the Import Timeline

Breakdown of the Import Process

The import process may be broken down to a few main areas:

1. Placement of Order

Finalization is the last stage of the importation process, where the order is placed with the supplier.

This stage is quite important because it forms the very foundation of the transaction as a whole. The major activities that are involved in this stage include:

Communication to the Supplier: Communicate the specification of the product to the supplier, such as dimensions, materials, and design details.

Agreement on Terms of Payment: This may involve pre-payments or deposits, payment on shipment, or letter of credit. It is necessary that these agreements be clear to avoid miscommunication at later stages.

Contract Review: Review and draft the contract to ensure all the terms are well defined, including delivery timelines, warranties, and penalties for delays.

Order Confirmation: Confirm the order in writing after all the details are agreed upon to cement the arrangement.

2. Production

After placing an order with the supplier, manufacturing of the machine starts, which greatly differs based on several factors.

Progress Update: Frequent communication with the supplier for progress updates shall facilitate managing expectations and also provide an opportunity to fix any probable problems well in advance.

Final Inspection: A final inspection may also be done before shipping to ensure that the machine meets the agreed-upon specification and standards of quality.

3. Shipping

Shipping follows after production whereby the machine is moved from the manufacturer to you. Considerations include:

Mode of Shipment: Once the mode of shipment is determined that is sea, air, or land shipment depending on budget, urgency, and nature of the machine. Air freight is expensive but it delivers goods faster. Sea shipping is generally cheaper for big-sized items.

Logistics coordination: This includes the coordination of logistics with freight forwarders to book transport, prepare shipping documents, and arrange pick-up.

Transit Time: Know the estimated time for shipment, which largely depends on the type and route of shipment.

Tracking: Avail of the tracking services to trace the progress of the shipment and the time that the arrival is expected.

4. Customs Clearance

Customs Duties and Taxes: There exist applicable customs duties and taxes that may really rack up the overall cost. Precise classification of goods is critical for the right duty classification.

Inspection: Customs may conduct an inspection to verify the contents of the shipment against the provided documentation. Delays can occur if there are discrepancies or issues.

Release of Goods: Once all duties are paid and the documentation is approved, customs will release the machine for delivery to your specified location.

Key Milestones in the Timeline

Key milestones that you should know to help you manage expectations include receipt of order confirmations, production start and completion dates, notification for shipping departures, and expected times of arrival.

Remembering these milestones will serve to smoothen communication with suppliers and to allow better planning on your part.

And More:

- Steps to Understand the Single Spindle Winding Machine Import Timeline

- Factors That Influence the Shipping Time of Single Spindle Winding Machine from China

- Quality Assurance in Yarn Color Card Machines: Chinese Supply Chain Strategies

Factors Influencing Shipping Time

Shipping Methods and Their Impact on Time

The choice among the different types of shipment significantly affects delivery times.

While air freight is generally considerably quicker, it is usually much more expensive and may well be unavailable for larger machines.

On the other hand, sea freight is cheaper but takes generally longer.

Proper understanding of the trade-offs that exist between speed and cost is thus pivotal for making an informed decision.

Customs Clearance and Its Role

Customs clearance has always proven to be an important bottleneck in the process of importation.

Delays at this stage are common and are usually caused by incomplete or incorrect documentation.

To avoid such risks, it is necessary that before shipment, all the papers relating to the goods dispatched, such as invoices and certificates of origin, must be intact.

This will ensure smooth customs processing and hence reduces the total time spent on imports.

Quality Control Measures

Importance of Quality Checks Prior to Shipment

Quality control before the dispatch of the machine will help you ensure the right machine specification is met.

Otherwise, this could save you from defects or performance discrepancies when it arrives.

A proper quality check may mean the difference between starting production well and costly delays.

Tips for Ensuring Machine Quality

To be sure that the quality of your winding machine is what suppliers may claim, request a profound documentation from the supplier detailing photos and specification.

Of course, whenever possible, arrange for a third-party inspection service, if necessary, to perform a pre-shipment inspection.

This added measure may give peace of mind and save dollars instead of costly mistakes.

Cost Considerations

Summary Cost to Import

The overall cost needs to be taken into consideration when importing a single spindle winding machine in order to correctly develop the budget for such an operation.

The major components of the cost of a single spindle winding machine include:

1. Purchase Price

The original price of the machine, which will be estimated with the supplier, including basic price and options selected, and possible discounts negotiated.

2. Shipping Fees

Shipping expenditure varies widely, depending on the chosen mode of delivery: air, sea, and land. Factors that can affect shipment fees are as follows:

Distance: The longer the distance, the more expensive shipment will be.

Weight and Dimension: The heavier and bigger a machine is, the more shipment fees it will require.

Shipping Method: Generally speaking, air freights are costlier compared to sea freights but faster.

3. Insurance

Insurance against loss or damage in transit, therefore, is recommended.

The cost of insurance normally depends on the value of the machine and the method of shipment chosen.

4. Customs Duties and Taxes

Customs duties and taxes are levied on all machinery upon arrival, usually depending on the value, origin, or other features.

It is very important to find out the applicable rates in order to avoid surprise costs.

5. Handling Fees

These are charged by shipping companies or port authorities for handling the shipment in question at various stages, both at loading and unloading.

6. Brokerage Fees

In case you use services of a customs broker who is able to facilitate the clearance process of your goods, their cost will need to be factored into your budget.

Hidden Costs to Be Aware Of

Aside from the principal cost, there are quite a number of hidden expenses which might always arise during the import process, which could have an impact on your general estimate of the budget:

1. Storage Fees at the Port

Customs clearance delays, or inability to take delivery on time, may result in storage charges.

Depending upon the size of the machine or perhaps delay in your shipment, this cost can add up fast.

2. Unexpected Tariffs

Unpredicted changes in trade policy or tariff can give rise to unforeseen costs.

Keep yourself updated with any proposed modification that may affect your import, particularly when the two countries are engaged in active trade negotiations.

3. Currency Exchange Rates

When the payments are in foreign currency, then the currency exchange rates can have a great impact on the overall cost of the machine.

Use forward contracts and any other hedging mechanisms in order to avoid such risks.

4. Inspection Fees

Based on the country regulation there may be some extra costs for inspection fees.

If customs would decide to inspect further more your shipment then this may create a cost and delay as well.

5. Documentation Fees

Preparing the documents you need may carry some costs, especially if you are using a professional service.

Ensure you are knowledgeable about all the documents required so that you don’t bear additional, unforeseen charges.

6. Miscellaneous Costs

Other associated costs may include local delivery fees once the machine has cleared customs, training for your staff in how to use the machine, or modification costs if changes need to be made post-delivery.

Conclusion

Importing single spindle winding machines from China is a great opportunity for any enterprise desiring to upgrade its production lines.

For this respect, the article will show crucial information regarding importation, like how to select the proper machine, manage timelines, and cost of importation.

More so, your investment in these machines, if well planned and attention to minute details paid to, will go a long way toward ensuring maximum efficiency with profitability.

Whether your firm is expanding its line of production or commencing a new project, this guide will furnish the foundational knowledge to confidently sail through the import landscape.